Plastics, made from polymers like Polyethylene (PE) and Polypropylene (PP), are essential in modern life, from food packaging to automotive parts. As demand grows, the future of the plastics industry is shifting to focus on reducing environmental impact, increasing recycling, and developing sustainable alternatives.

Plastics are a crucial part of our daily lives and have become the building blocks of our modern world. Daily tasks such as shopping for food, brushing our teeth, driving a car, or buying a cup of coffee would look very different without this vital material. The ubiquitous plastics we use daily are made from polymers, which are the chemicals that get heated up and molded to help create everything from children’s toys to aircraft interiors.

Polyethylene (PE) and Polypropylene (PP) are two of the most common polymers in our modern society, each with distinctive characteristics that make them essential for producing everyday products from food packaging to automotive parts. With the growing demand for plastic and the outlook of the polymers market showing no signs of slowing down, plastics are increasingly negatively impacting our planet. Reducing plastic use, increasing recycling, and developing new alternatives are crucial to help shape the future of the polymers industry to ensure long-term competitiveness.

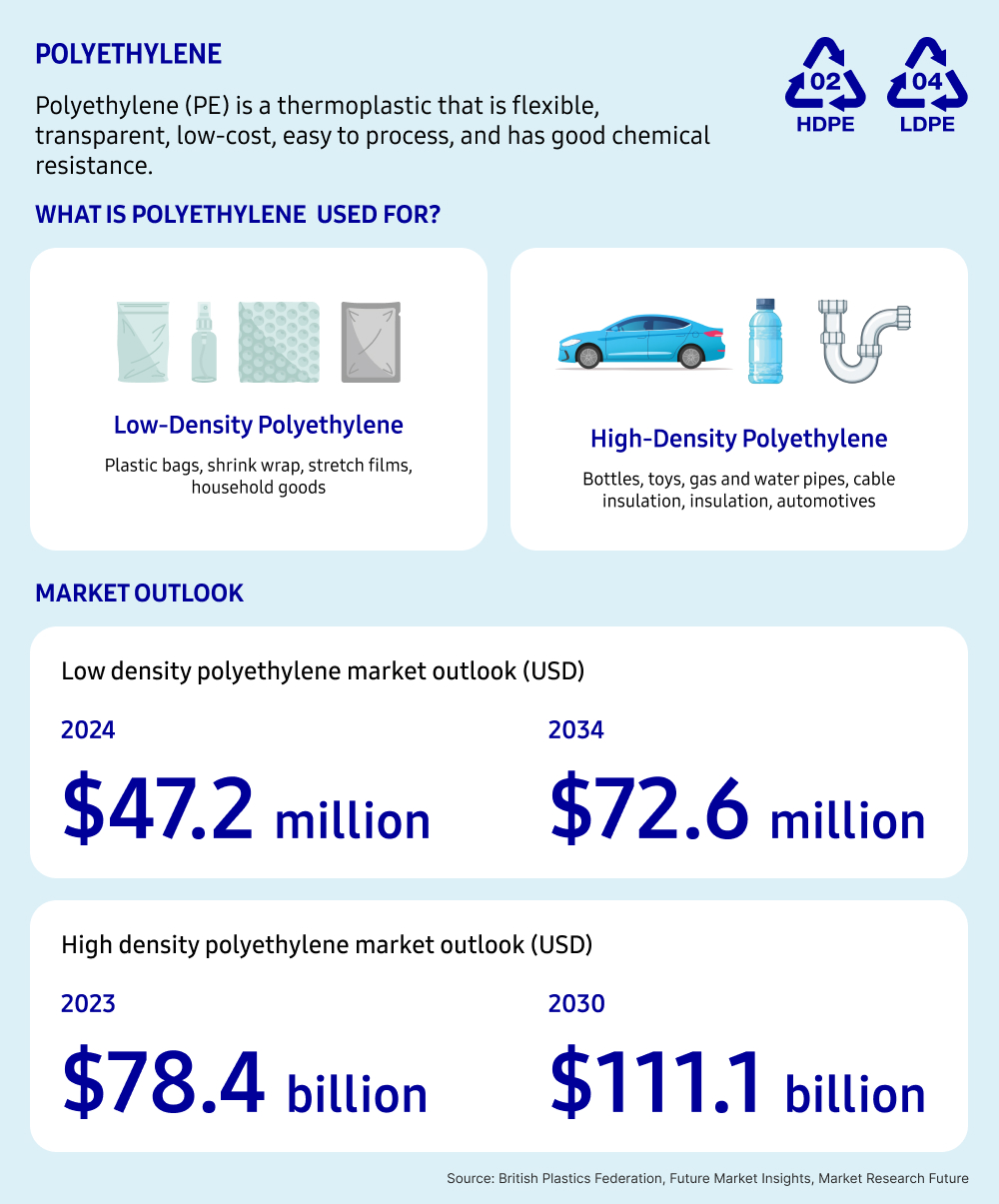

What is Polyethylene (PE)?

Polyethylene, a thermoplastic derived from petroleum or natural gas, is widely available in three main forms: Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), and Linear Low-Density Polyethylene (LLDPE). LDPE is known for its flexibility and transparency, making it ideal for packaging materials like plastic bags. HDPE, by contrast, is more rigid and durable, commonly used in pipes and heavy-duty containers. LLDPE combines the qualities of both, offering toughness and flexibility. Polyethylene is used in the packaging, infrastructure, and automotive industries.

What is Polypropylene (PP)?

Polypropylene (PP) is a thermoplastic and a synthetic resin used for its high strength and stiffness and is more robust than polyethylene. It is used extensively in applications requiring durability, such as automotive components, textiles, and packaging. Although it has a limited availability compared to polyethylene, its unique properties make it indispensable across industries.

Innovations Shaping the Future of the Plastics Industry

According to the United Nations Environment Programme, around 9.2 billion tons of plastic has been produced since 1950. With the demand for plastic increasing, the future of plastic polymers relies on advances in recycling technology and sustainable alternatives, such as biodegradable plastics.

- Circularity

Closing the loop on plastic waste is a global priority, ensuring that the production, usage, and disposal of plastic is managed in a sustainable way. Recent initiatives, like the EU-led Circular Plastics Alliance, aim to boost the market for recycled plastics and ensure that 10 million tonnes of recycled materials are integrated into new products by 2025. This shift is part of a broader movement toward a circular plastic system, which seeks to reduce the reliance on virgin materials. To lessen plastic leakage and the carbon footprint, the OECD suggested increasing the use of secondary plastics. Negative environmental impacts can be reduced by reusing waste materials and transforming the entire system to be more circular.

- Plastics Recycling

Mechanical and chemical recycling methods have evolved to improve the conversion of plastic waste into reusable materials, though mechanical recycling often leads to quality degradation. In contrast, chemical recycling processes like pyrolysis and gasification offer solutions for handling more difficult-to-recycle plastics. Innovations such as AI-enhanced sorting systems and advanced recycling facilities are driving more sustainable practices in plastic recycling.

- Biodegradable Plastics

Biodegradable plastics can degrade more rapidly than regular plastics and are becoming increasingly important in reducing the environmental impact of traditional materials. As global decarbonization efforts accelerate and governments enforce stricter carbon-reduction programs, the demand for biodegradable alternatives continues to rise.

Global Polymer Market Trends and Outlook

The global plastics market was estimated to be valued at $712 billion USD in 2023 and is expected to grow to $1050 billion USD by 2033, with a compound annual growth rate (CAGR) of 4% over a ten year period. This expansion is largely driven by increased demand in the infrastructure, automotive, and electronics industries.

Plastic Polymer Demand by Region

- Growth is particularly strong in the Asia-Pacific region, which accounted for over 22% of the global market in 2023. Countries like China, India, Vietnam, and Indonesia are experiencing rapid industrialization, driving demand for polymers in sectors like construction and manufacturing.

- North America and Europe are also major players in the polymer market. In North America, the healthcare sector, particularly the demand for medical-grade polymers used in surgical instruments and disposable devices, continues to fuel growth. In 2023, the United States plastic market had an estimated value of $90.5 billion USD.

Regions are facing challenges from supply chain disruptions caused by geopolitical tensions and the lingering effects of the COVID-19 pandemic, leading to raw material shortages, price fluctuations, and production delays. These disruptions are accelerating the need for rapid innovations in the industry.

Samsung C&T’s Role in Global Polymer Trading

Samsung C&T Trading and Investment Group has been a key player in the global polymer trading market for over 30 years. The Group provides essential materials to industries like home appliances, automotive, construction, and packaging. By leveraging its extensive network in regions like North America, Vietnam, and Thailand, Samsung C&T ensures a steady supply of high-quality polymers to meet evolving market needs.