How much time would you need to build a house of around 400 square feet from scratch? Perhaps a few months, involving a crew of workers working day and night?

In March this year, a San-Francisco based startup built a fully functioning residential home near Moscow in just 24 hours. At a cost of around US$10,000, the crew deployed one machine to achieve all this – a 3D-printing robot.

This astonishing accomplishment in Russia is just one of many success stories emerging in recent years which give us a glimpse of the future of construction. Dubbed the “fourth industrial revolution” by observers, the latest technological innovations are set to dramatically change the way we build.

Into the Digital Realm

They say construction companies are accounting companies which happen to erect buildings, as number crunching has always been a big part of the industry. Not only that, but all construction projects, no matter how big or small, involve many different parties working together.

It’s no surprise then that digital technologies and processes are fast gaining traction in the construction industry, as they are capable of processing large data pools and allowing multiple parties to collaborate.

As the World Economic Forum notes, “[digital technology and processes] enable new functionalities along the entire value chain, from the early design phase to the very end of an asset’s life cycle at the demolition phase.”

The use of big data and analytics is one key development in the construction industry’s move toward digitalization. What’s the best location to build a bridge? Will weather conditions affect a project’s completion date? And when should a road be repaired? Algorithms analyzing huge data pools can now generate previously unobtainable insights for such questions, minimizing the guesswork in the decision-making process.

Constructors are increasingly looking to Building Information Modelling (BIM) as the digital solution to enhance building design and coordination. Beyond showing 3D versions of blueprints, BIM allows different building professions to exchange a wide-range of information, such as cost and time, on a centralized platform, providing a holistic view of projects.

Brick by Brick, with Robots and Drones

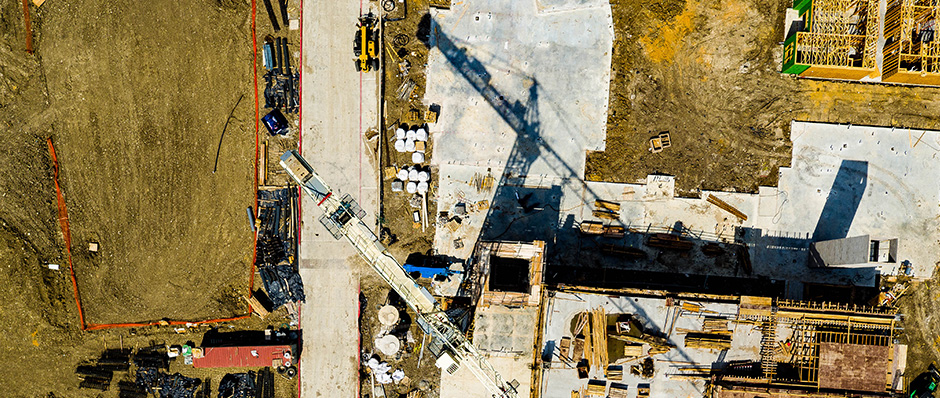

Workers laying bricks, drivers operating trucks, and surveyors mapping construction sites – all these site activities could soon be automated.

Compared with other industries, automation is still relatively uncommon in construction. But as scientists make great strides in robotics and artificial intelligence, machines are quickly gaining the ability to complete labor-intensive tasks. The cutting-edge robot SAM100, for instance, can build a wall six-times faster than a human bricklayer. The Japanese construction machinery manufacturer Komatsu, meanwhile, made headlines with their automated bulldozers.

Efforts are already underway to apply innovations in the field of unmanned aerial vehicles (UAVs) and 3D mapping technology to construction. Major players in the industry like Bechtel and AECOM, for instance, have enlisted the services of US drone mapping company Skycatch to radically change the surveying process. While mapping construction sites typically takes days or even weeks, drones – equipped with sensors and powered by topographic softwares – could shorten this process to just a few hours. In addition, they can be deployed to speed-up inspections, coordinate logistics, and offer real-time updates.

VR and AR: Future Tools of the Trade

Putting on a virtual reality (VR) headset maybe all it takes for engineers to visit building sites in the future. And this is just one of many ways VR and augmented reality (AR) could transform the construction industry.

In an industry where 12% of project costs goes into rework and remedial works, commentators anticipate that this figure could be drastically reduced with the adoption of VR and AR.

GE, for instance, has begun to use VR models of nuclear plants to train maintenance engineers in an area where hands-on experience is made difficult by the arduous process required to gain clearance.

“Before we had the virtual visit, you would wonder where machines would be inside the plant and how they would be linked,” GE manufacturing engineer Igor Ballaud told GE Reports, “Now, the virtual visit answers those questions. It’s as if you were in the power plant.”

Although currently not as widely adopted as VR, AR nevertheless holds vast potential application in construction. With its ability to project virtual images onto physical objects, the technology could help workers accurately build structures, as well as speed up maintenance by identifying problems quickly.

Construction 4.0: The Challenges Ahead

The construction industry has traditionally been slow at adopting new technologies. For over half a decade, building methods have remained relatively unchanged. But as the fourth industrial revolution gathers pace, inertia may not be an option for long.

To implement such changes, however, comes with challenges.

Technological refinements aside, the highly fragmented and horizontal nature of the industry means that it takes more than just a handful of companies to spearhead the transformation. Instead, the whole industry needs to act as a collective to truly realize the vast benefits and potentials of the latest technologies.

As a global leader in the field, Samsung C&T is committed to finding new solutions for construction and engineering. The company recognizes that using the latest technologies to improve and minimize waste can produce benefits for the wider economy, environment, and societies.