Have you ever wondered how long the longest bridge in the world would be? The Guinness Book of World Records lists China’s Danyang-Kunshan Grand Bridge as the longest bridge in the world. It was completed in June 2011 and stretches for 164 kilometers.

Bridges over rivers, lakes, streams and oceans can also be very long. The world’s longest sea crossing bridge is the Hong Kong-Zhuhai-Macau Bridge in China, at 55km long including its access roads. This article will look at bridges over water and how they are constructed.

Structure of bridges

A bridge not only has a functional aspect, but also a cultural dimension. Look at how some bridges come to stand in as symbols for a city: the Golden Gate Bridge is instantly recognizable as representing San Francisco, and Tower Bridge immediately reminds one of London.

What type of bridge to build in any given location will be determined by a number of factors including its length, the condition of the ground, cost, and available construction technology and materials. Some of the main bridge types are arch, beam, cantilever, suspension, and cable-stayed structures. Each has its own individual strengths.

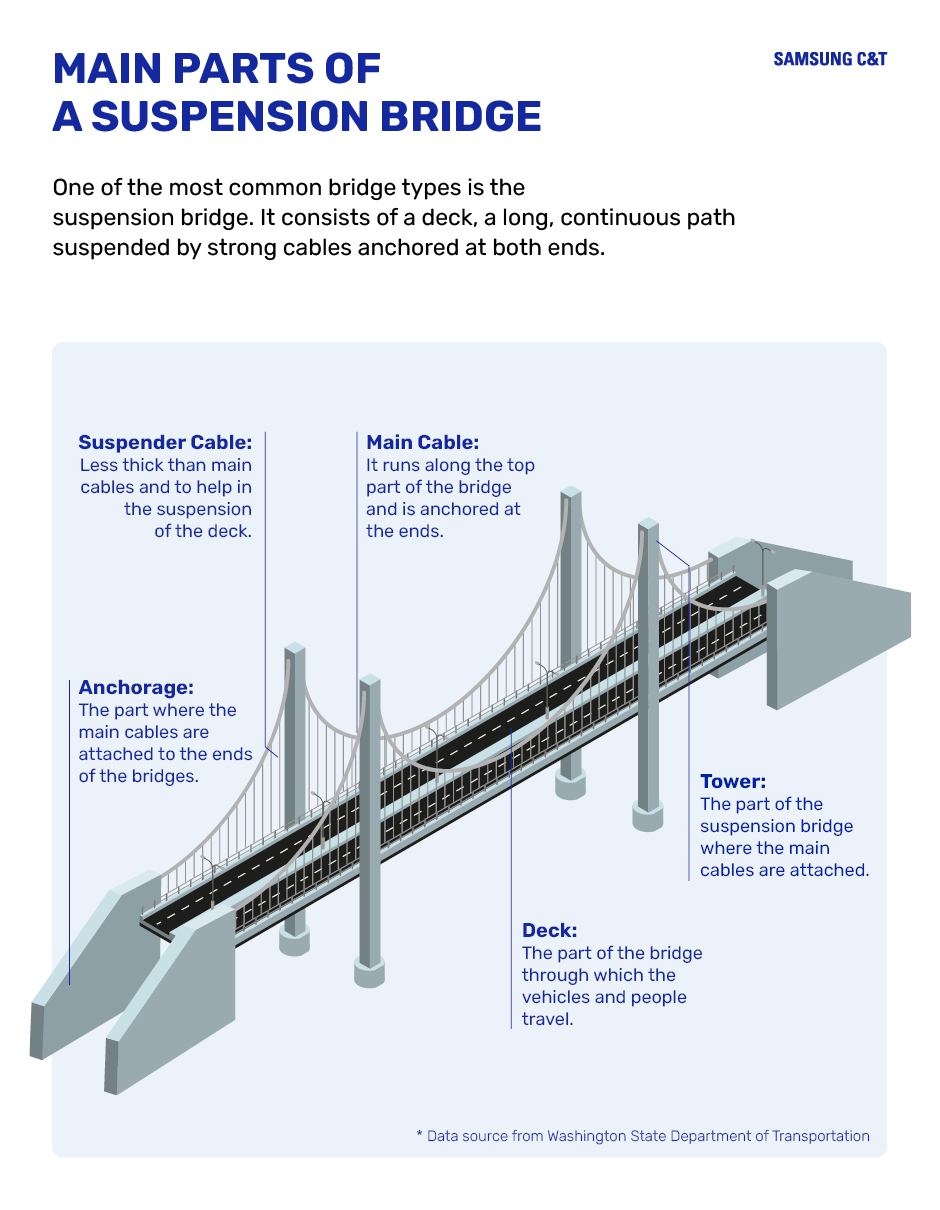

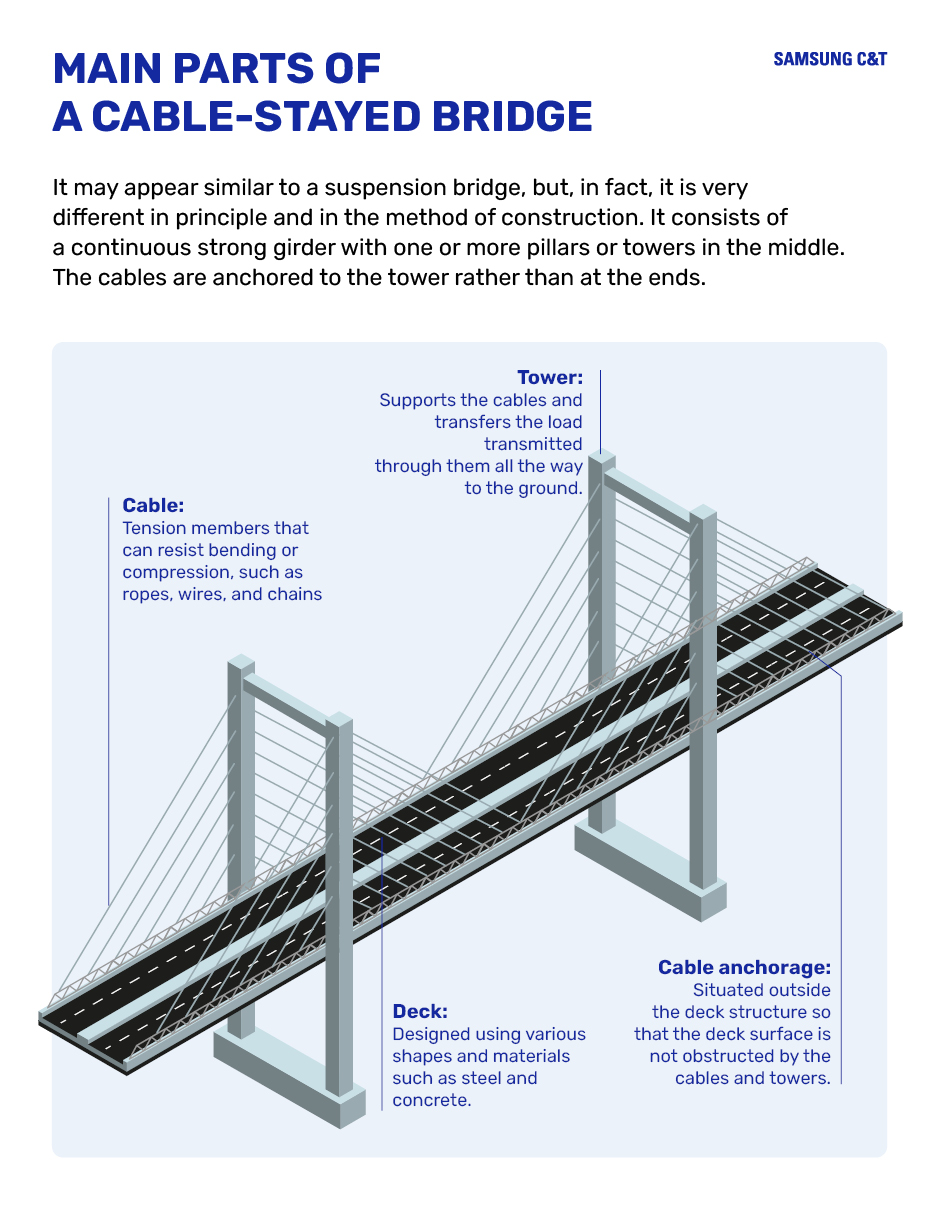

Before we delve into the process of constructing a bridge over water, it is helpful to remind ourselves of the component parts of suspension bridges and cable-stayed bridges, which are representative of long-span bridges.

How to construct foundations of bridges over water

When constructing a bridge over a valley or gorge, to a certain extent it can often be straightforward, but when a bridge goes over a body of water, a new wrinkle of complexity is added because at least some of the foundation will be underwater. To ensure stability, it is necessary to secure the foundation properly to the floor of the ocean, lake, or river, so that the bridge does not get washed away by the flowing water.

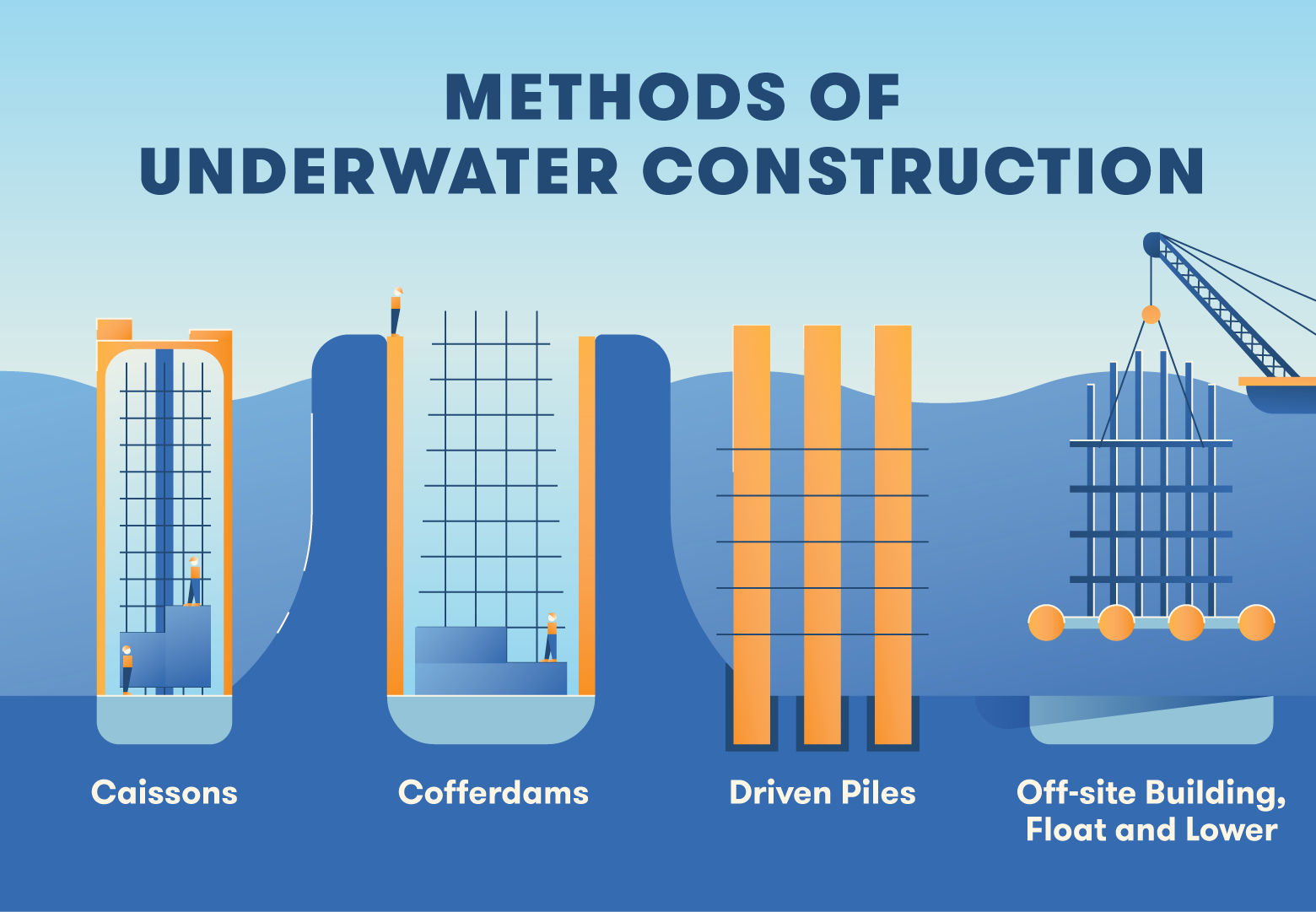

Four major techniques have been developed and refined over the years to build solid underwater foundations to suit the conditions and the type of bridge.

Caissons are large hollow structures that are lowered into the water down to the ocean floor or river bed. Water flows around these structures, and inside them, workers can excavate through the loose sand to reach the solid bedrock. At that point, a caisson can be filled with concrete and it becomes part of the bridge’s foundation. In a pneumatic caisson, compressed air is used to maintain pressure inside the caisson and keep water out.

A cofferdam is a temporary circular structure built in the water out of heavy timber, rocks, or, these days, steel. Like a dam, the cofferdam holds back the water, which flows around the space enclosed by it. Water is then pumped out of the enclosed area, making it dry and possible to work in, for example by pouring concrete or constructing a steel structure.

Both cofferdams and caissons are used because it is difficult for humans to build underwater. The third technique is a little different. Similar to driving a nail into a piece of wood, a pile driver is a machine that can drive hollow metal tubes called piles into the underwater bedrock from above. These steel tubes can then be filled with concrete to make it solid and add strength. In this way, there is no need to divert water at all.

The last technique is to build the foundation of a bridge off-site, for example in a factory, transport it to the body of water, load it on a barge and tow it out to where it is needed, and then lower the structure into the water down to the bottom. Once it has been lowered, the structure can be fastened to the bottom with piles, for instance.

Using these technologies, useful and beautiful bridges are being built, and Samsung C&T is also applying these technologies to bridge construction. Let’s continue to learn about the bridges built by Samsung C&T Engineering & Construction Group.

Bridges built over water by Samsung C&T Engineering & Construction Group

Samsung C&T Engineering & Construction Group constructs world-class bridges over water. For example, the 4.42 km Yeongjong Bridge was built between 1995 and 2000 by Samsung C&T E&C Group. For the first time in Korea, the pneumatic caisson technique was used to construct the underwater foundation of this bridge. The Incheon Bridge, the longest bridge in Korea with a length of 18.38 km, was also constructed by Samsung C&T. In addition, the main span length of the cable-stayed bridge in the main route is 800m, making it the fourth longest in the world at the time of its completion.

Samsung C&T E&C Group has also built bridges over foreign waters. In Qatar, the Lusail CP3A is the world’s first suspension bridge with a circular pylon. The 2.2 km-long Mersey Gateway Bridge, one of the UK’s leading infrastructure construction projects, was also completed by Samsung C&T E&C Group in 2017.

For a more in-depth review of bridges over ocean, check out our June 2020 article Like a bridge over salty water.