Sulfuric acid is a crucial chemical used to clean and etch silicon wafers that are found in semiconductors, the chips in the electronics we use daily. Discover more about this process and gain insight into the market outlook for sulfuric acid.

The devices and electronics we use daily are made up of hundreds of components using a wide range of metals and chemicals. A significant component of our electronics is semiconductors, the electronic microchips that enable devices to communicate. These are found in technologies such as renewable energy systems, healthcare devices, and cars.

Semiconductors are made via an intricate manufacturing process. As this process has become more sophisticated, our electronics have become smaller and more advanced. One component of this process crucial to ensuring the high-quality production of semiconductors is the chemical sulfuric acid used for cleaning.

What is Sulfuric Acid?

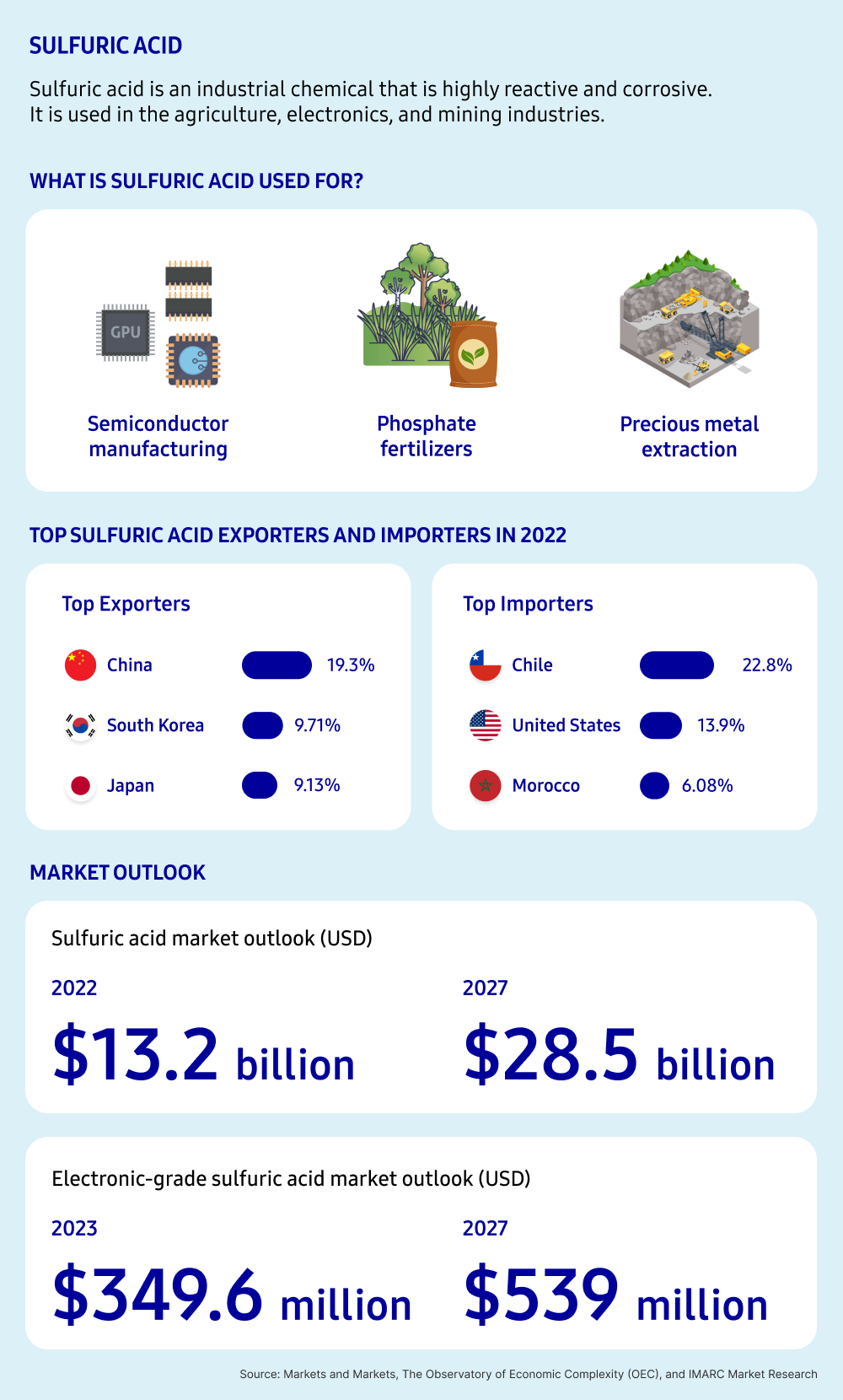

Sulfuric acid is an industrial chemical that is highly reactive and corrosive. It is used to produce the fertilizers that help grow the food that we eat and extract the precious metals used in electric batteries and solar panels, owing to its ability to dissolve rocks. The sulfuric acid market is expected to grow to USD 49.9 billion by 2032, driven by food consumption and electronics demand.

Electronic-Grade Sulfuric Acid and Semiconductors

A highly pure form of sulfuric acid known as electronic-grade sulfuric acid is used for cleaning and etching computer chips that are used in the electronics and devices we use in our daily lives. These computer chips are known as semiconductors that are essentially the “brains of modern electronics.” Semiconductors can be found in smartphones, computers, cars, wind turbines, pacemakers, and insulin pumps.

How is Sulfuric Acid Used to Make Semiconductors?

Sulfuric acid is used in semiconductor manufacturing to remove organic residue from silicon wafers and during the photoresist stripping stage. Silicon wafers are thin slices of crystal that form the foundation of semiconductors, integrated circuits, and other small devices. This is how California’s Silicon Valley, home to some of the world’s largest tech companies, got its name.

During production, silicon wafers are cut into circular shapes and must be meticulously cleaned to eliminate impurities and organic residues. This is where electronic-grade sulfuric acid comes into play. Due to its high concentration, it effectively cleans the wafers and removes layers of the “photoresist” coating—a light-sensitive material used to reveal the intricate microstructures that form on the wafers. These wafers are then ready to be turned into the brains of the electronics in our phones, computers, and solar panels!

Market Outlook for Sulfuric Acid

There are a range of industries driving the demand for sulfuric acid, including agriculture, metal processing, and petroleum refining. As populations increase around the world, the demand for sulfuric acid, a crucial ingredient used in phosphate fertilizers, will be driven by the demand for increased food consumption. In 2022, the sulfuric acid market size was valued at $13.2 billion USD and is projected to grow to $28.5 billion USD by 2027, exhibiting a compound annual growth rate (CAGR) of 11.7%.

The United States, China, Russia, Morocco and India are the top countries driving the demand for sulfuric acid worldwide. The Asia Pacific region is the largest regional market for sulfuric acid, with China exporting $638 million USD of sulfuric acid in 2022, South Korea exporting $321 million USD, and Japan exporting $302 million USD.

Electronic-Grade Sulfuric Acid Market Outlook

In 2023, the global market for electronic-grade sulfuric acid was valued at $349.6 million USD. This is predicted to increase to a value of $539 million by 2032. This growth will be driven by the high consumption of sulfuric acid in the semiconductor and PCB panel industries and the rapid increase in renewable technology development. The Asia Pacific region holds market dominance due to being the home of some of the world’s largest semiconductor manufacturers.

There is also a growing demand for semiconductor materials in the United States for strengthened domestic production. In a report from the Semiconductor Industry Association earlier this year, the United States is targeting to triple its chip manufacturing capacity by 2032 with its bipartisan CHIPS Act.

Samsung C&T’s Strategic Role in the Expanding Sulfuric Acid Market

Samsung C&T’s Trading and Investment (T&I) Group is actively engaged in the trading of various industrial materials and chemical products with the objective of trading essential industrial materials and developing sustainable businesses. Recently, the T&I Group participated in a joint venture with DSM to develop sustainable business opportunities in materials trading, including materials required for semiconductor manufacturing.