Marble has been prized for thousands of years as an expression of luxury and the material that helped produce some of the world’s greatest artistic sculptures. Like fine wines, marble varieties and their features have become strongly associated with their locations. One such example is statuario marble, which can only be quarried in the Italian city of Carrara located in northern Tuscany.

Characterized by its warm or cold white coloring and gray veins, statuario was famously used by Michelangelo to carve some of his most popular works, including the renowned portrayal of mourning, Pieta.

Aside from sculptures, statuario may also be spotted in buildings, as its qualities make it a highly appealing construction material. This fact was not lost on Samsung C&T’s Engineering & Construction Group, which has so far used around 10,000m2 of statuario panels in its ongoing project to build DAICEC in Mumbai, India. Standing for Dhirubai Ambani International Convention and Exhibition Center, DAICEC is set to be one of the world’s biggest and most attractive mixed-use developments.

Choosing the best marble

Kim Jin-eon, DAICEC site manager, explains the main reason for using statuario is “the natural beauty of its color and pattern.” He admits to being inspired by his own experience of seeing “the brilliant colors” of Pieta when he visited Rome five years ago.

But choosing to build with this type of marble is just the first step. Then comes the decision over which individual blocks to use. Typically, large blocks are taken up from a quarry and then cut into slabs, which are then further cut according to required specifications. The entire process from block selection to processing takes approximately six months.

“Selecting the right block of marble for the design intent is, of course, immensely important and involves taking a variety of factors like color, pattern and consistency into consideration,” Kim says.

Moreover, high-grade statuario is in short supply after so many centuries of demand, and that has driven up its price, although Kim insists “one can’t expect to get the best without paying a premium.”

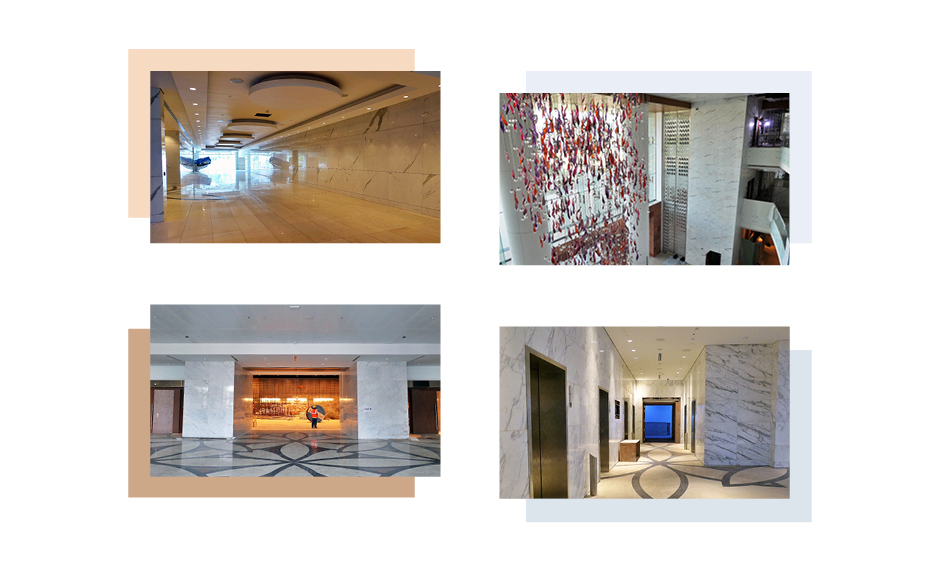

Lobbies lined with luxury

The DAICEC building features four lobbies that consist of three floors and are each 200m long – and the entire surface of these massive lobbies is covered in statuario. One way to make more efficient use of this precious marble is to make layered panels using other materials.

“We decided to fabricate 30mm-thick finishing panels by attaching 25mm-thick cultured marble panels to the backs of 5mm-thick statuario panels,” Kim explains. “This is actually a common approach at many project sites like ours because it makes it possible to get all the benefits of natural marble while ensuring high degrees of durability and constructability.”

Even at 5mm in thickness, however, the amount of statuario used at DAICEC to date would be enough to cover almost two football fields.

Another painstaking detail is ensuring the vein patterns on all the individual marble slabs produce a cohesive overall look, especially as high-grade statuario is prized for its colors.

“We primarily used two panel configurations,” Kim says as he outlines how his team put the slabs together. “One is with the panels arranged so that the veins seem to flow in one direction, and the other is a book-matching arrangement in which the vein patterns on one side mirror the vein patterns on the other.”

The effect is a luxurious lobby environment that may inspire countless future visitors to DAICEC, even if these are flat slabs of statuario. After all, it was Michelangelo who was quoted thus: “The marble not yet carved can hold the form of every thought the greatest artist has.”