You cannot build a tall structure without a device to lift heavy objects to great heights. The most common such device is a crane, something that people have used for eons to lift things higher than human arms can reach, and to move things heavier than human hands can carry. Today’s cranes are taller than ever. But how do they work and how do they make themselves taller?

How do cranes work?

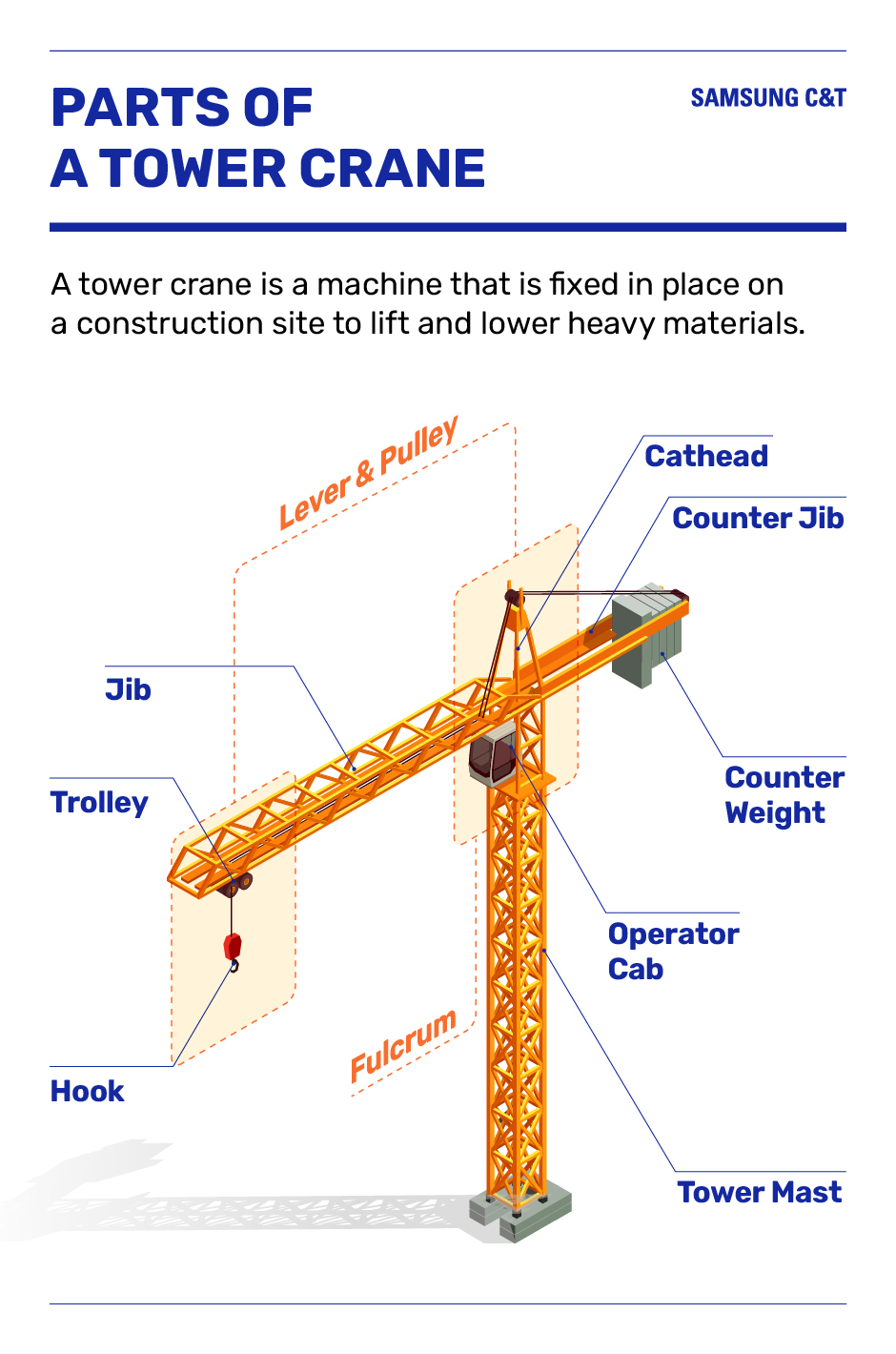

To understand how a crane works, one must first know the principles of levers and pulleys. In its most basic form, a lever is a simple machine consisting of a horizontal beam attached to a hinge called a fulcrum. Together they amplify an input force to produce a greater output force. In this way, using the principle of leverage, it is possible to use a using a relatively light counterweight to lift a heavier load.

A pulley is another simple machine consisting of a wheel on an axle and a rope, cable, or wire that passes over the wheel. One end of the rope is pulled downward, and the other end is lifted upward, hoisting a load into the air.

Cranes combine both a lever and a pulley system to raise a load high onto a building under construction. While cranes can be mobile and come in many configurations, this article will focus on a fixed jib tower crane. Fixed jib tower cranes are a common sight on construction sites around the world. They are notable for their ability to not only lift heavy objects to great height but also to seemingly “grow” bigger.

A safe tower crane begins with a strong, solid foundation that is securely fixed to a flattened area of ground. The mast, the vertical part of the crane, is made up of several trusses, or sections, the first of which is secured to the foundation with anchor bolts.

Above the mast’s top truss sits a slewing unit allowing 360-degree rotation, or slewing. The cathead, where the controls and operator cab are, sits atop the slewing unit. From the front of the cathead extends the jib attached to a pulley and hook system that lifts the weight. The jib is balanced behind the cathead by a shorter counter jib, attached to a counterweight. Using the principle of leverage, the cathead is basically the fulcrum, and the jib and counter jib together form the beam of the lever. By altering the distance of the hook and pulley from the fulcrum, the jib can lift objects of varying weights above the ground.

How do cranes climb or grow?

The jib can reach up to approximately 230 feet long, at which point the crane can lift up to 19.8 tons. In addition, using a tower crane has the advantage of being able to rotate 360-degree rotation thanks to the slewing unit.

In order to construct a tall building with a tower crane, it is necessary to make a tower crane taller. This process is called “climbing,” and it must be carried out painstakingly to ensure the stability of the crane and the safety of all personnel.

A climbing frame is attached to the outside of the mast and rises just below the cathead. When the climbing frame lifts the top of the crane via hydraulics, a space is created between the cathead and the mast. The new mast section is lifted off the ground by a hook and placed between the cathead and the mast. The process can be repeated to add new sections of the mast one after another.

Please refer to the video below to understand the way the tower crane climbs.

The importance of safety

As with any kind of work involving heavy objects and high altitudes, safety must be the number one priority when a tower crane is in operation.

For example, when raising objects, one must be careful to make sure that nobody is standing directly beneath or in the proximity of the crane’s hook. One must also pre-check the rope or cable used to lift any load. Also, when a tower crane is climbing, it is important that the jib does not slew, because that can place excessive torsion on the mast or the climbing frame.

Samsung C&T Engineering & Construction Group’s equipment team is taking the lead in securing safety and modernizing construction based on its leadership in equipment technology. The Group understands the essential importance of safety and is constantly working to educate its workers and partners about it too, and to ensure that appropriate steps are made to ensure that everybody at its construction sites has a safe day at work every day.