Grinding media plays a crucial role in mineral ore processing by breaking down rocks and materials into finer particles. Discover more about grinding media and its types, applications, and future market outlook.

Each year, billions of tonnes of mineral ores and metals are mined globally. Mineral ores are rocks that occur naturally in our environment. These mineral ores contain vital metals and minerals used to create everything from smartphones to apartment buildings.

This article will explore what happens after mineral ores are mined and how grinding media helps create the foundation for the materials that build our world. Continue reading to learn more about grinding media and how Samsung C&T Trading and Investment Group is involved in the grinding media trading business.

What is Grinding Media?

Riverways and oceans have been grinding rocks down into fine particles through erosion for billions of years. On a mass-production scale, materials called grinding media are used to break down rocks and materials into finer particles to be used for a range of industries. Grinding media are metal balls or rods used to grind up rocks, cement, and mineral ores.

Applications of Grinding Media

Grinding media is used to crush materials used for manufacturing, construction, and at power plants to grind coal or biomass to produce energy. Chemicals, pharmaceuticals, cosmetics, pigments, paints, food, and beverages also use grinding media of various shapes and materials on a large scale.

Types of Grinding Media

Grinding media come in various shapes, sizes, and materials. Materials used to make grinding media include steel, aluminium, chromium, and even glass. Grinding media is selected based on the type and volume of material being processed and is considered based on the final desired particle size.

Balls made from steel, cast iron, or ceramic materials are used widely as grinding media. They are recognized for their efficiency and durability and can be used in ball mills. Ball mills are machines where grinding media rotate continuously to crush mining ores and other materials. Other grinding media types include tapered cylindrical cylpebs, rods, and flat shapes with a wider surface area.

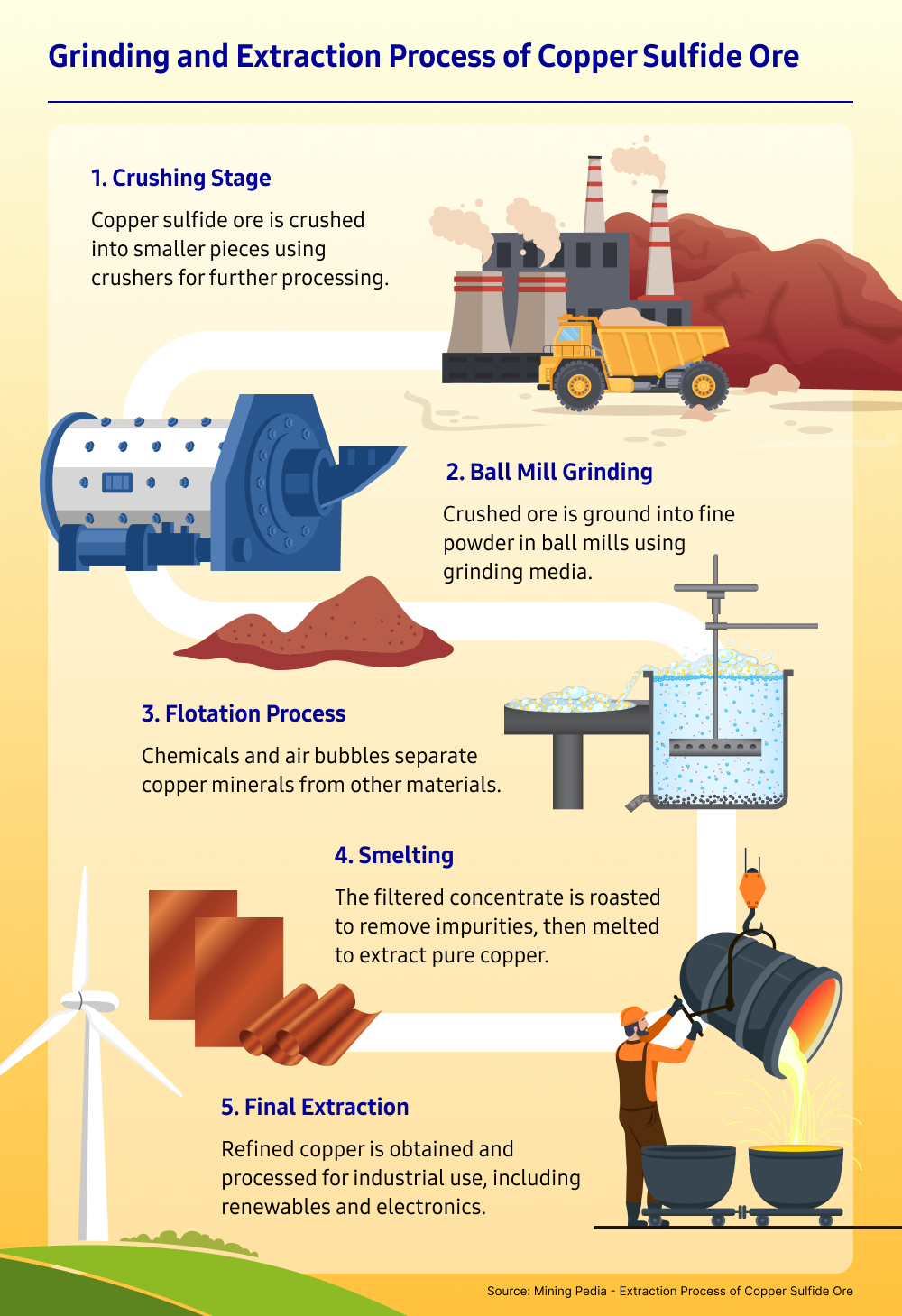

What Materials Are Processed Using Grinding Media?

Steel balls and rods are powerful grinding media used to grind mineral ores, limestone, rocks, and cement in the mining and construction industries. They are also used to extract precious metals in the copper and gold industries.

Ceramic balls are used to grind materials used in pharmaceutical, cosmetic, or food products as they prevent contamination.

Market Outlook for Grinding Media

In 2023, the grinding media market size was valued at an estimated $7.69 billion USD. Projections show that the market is expected to grow to a value of $10.55 billion USD by 2032 at a compound annual growth rate (CAGR) of around 3.58% during the forecast period.

Demand Outlook for Grinding Media

Demand drivers for the grinding media market include the increasing need for minerals across the construction, mining, and manufacturing industries. Materials like copper are also used to make clean energy technologies such as electric vehicle batteries and wind turbine generators.

Further demand for grinding materials within the mining industry is the rapid development of new and more efficient grinding equipment coming into the market, encouraging the industry to upgrade and invest in better technology to enhance productivity.

Grinding Media Market Segmentation

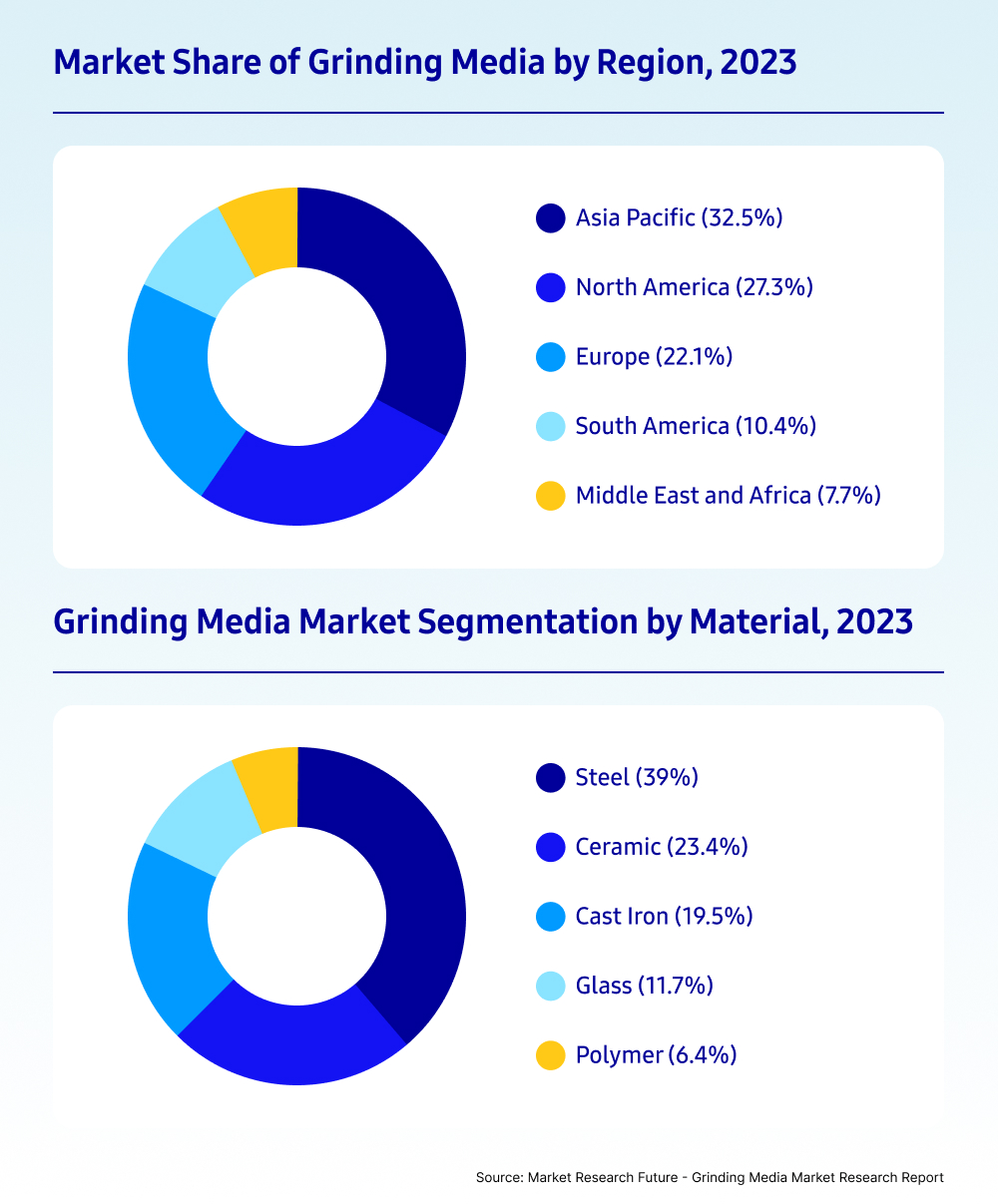

The Asia Pacific region holds the largest share of the grinding media market ($2.5 billion USD) due to its manufacturing and mining industries, followed by North America ($2.1 billion USD), which also has a strong industrial sector.

By material, steel grinding media makes up the largest portion of the grinding media market and was valued at $3 billion USD in 2023. Following steel, ceramic grinding media was valued at $1.8 billion USD and is commonly used for pharmaceutical and food processing.

Samsung C&T Trading and Investment Group’s Grinding Media Business

The Samsung C&T Trading and Investment Group supplies essential chemicals and materials for mining operations, meeting customer needs through midstream functions. Our offerings include trading and supply chain management (SCM) for sodium cyanide, off-the-road tires, grinding media, and flocculants. We primarily serve markets in Africa, Türkiye, Kazakhstan and South America and continue to pursue new business opportunities for market expansion.