Creative thinking has become the norm for the scientists fighting climate change. Some believe the secrets of the rainforest canopy, the so-called “last biotic frontier,” could arm ecologists with the knowledge they need to safeguard the future of the planet. And that is why an international team of ecologists from three continents is now attempting to unlock the secrets of the rainforest canopy. Their equipment? A network of construction cranes.

According to media outlet Phys.org and the British Ecological Society: “Instead of moving steel girders and concrete blocks around urban construction sites, cranes enable ecologists to carry out detailed experiments in tree tops. The cranes’ moveable arms let them reach up to 2 ha of forest.”

Meanwhile, in Scotland, teenagers are raising money for charity by bungee jumping from 46m cranes, while these tall machines are also providing vital training for firefighters.

Diverse, multifaceted and completely indispensable to modern constructors – a world without cranes is becoming increasingly hard to imagine.

Cranes of Yesteryear

Although most people think of construction cranes as modern construction innovations, they are almost as old as time itself. Archeologists have discovered that the Ancient Greeks used early cranes to build the Temple of Artemis, one of the Seven Wonders of the Ancient World. Crane mechanics are one of the main subjects of Mechanica, an ancient engineering manual possibly written by Aristotle.

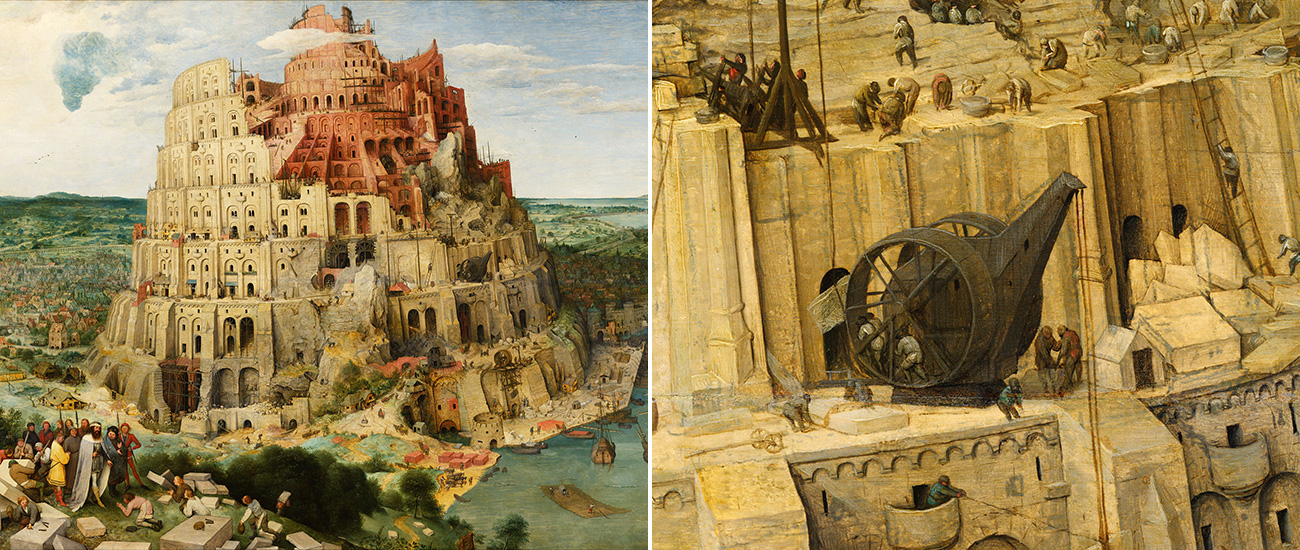

By the Middle Ages, cranes had become relatively sophisticated, and a complex double-treadwheel crane device is depicted in Pieter Bruegel’s dramatic 1563 painting The Tower of Babel.

The painting shows two men walking on a wooden treadmill-powered crane, hoisting a large block of stone up the giant tower.

The first mechanized cranes began to appear during the Industrial Revolution. The father of the modern crane was William Armstrong, the inventor of the hydraulic crane, as well as its engine, the hydraulic accumulator.

Once he had perfected his creation, he began producing cranes commercially – selling them as devices intended to load heavy quantities of coal onto barges. The inventor’s machines were so effective that Venice Dockyard continued to use its distinctive 19th-century Armstrong crane until the 1950s.

Right Tools for the Job

In modern times, the crane has diversified beyond even the imagination of pioneers like Armstrong. Sabah Alkass, a professor at the Department of Building, Civil & Environmental Engineering at Concordia University in Canada, says, “Material handling is an important part of the delivery process of construction projects – and cranes are the most important resources used in achieving this, especially on a construction site.”

Few construction jobs can make do without a crane of some sort: whether it be a fixed tower crane or a moveable mobile crane.

From the mighty LTM 11200-9.1, which can extend to 100m high and lift the equivalent of 12 blue whales, to tiny truck-mounted hydraulic cranes – builders use the lot.

Tomorrow’s World

With construction innovation at an all-time high, engineers and IT pioneers alike are now joining forces to design new devices that will take the crane to dizzying new heights.

Researchers at India’s Veermata Jijabai Technological Institute (VJTI), recently unveiled plans to create a self-balancing crane designed to “eliminate the risk of human errors that lead to accidents.” The VJTI’s Vidhan Agrawal explained, “It’s a completely automatic android-controlled tower crane. Its electronic hardware lets it calibrate its position […] and reduces the chances of the crane toppling.”

Meanwhile, digital-age innovators are starting to change the way cranes work, with innovative software solutions. These include features like a programmable, customizable OS for crane operators, allowing for remote operation, and cranes that perform self-diagnostic tests – informing operators of production risks and potential accident hazards.

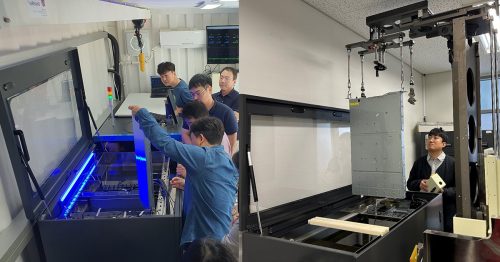

Constructors like Samsung C&T are aware of the need to stay abreast with the latest developments in crane technology. When the time comes to bring in crane operators and technology – as is so often the case for many of the company’s high-rise projects – in-depth knowledge of crane innovation is indispensable.

Lofty Future

Whether your goal is to lift a large prefabricated slab of building materials, a hefty generator unit – or even explore a rainforest canopy – chances are you will need a crane to do it.

And with technology advancing by the day, there are plenty of pages still to be written in the far-reaching history of the construction crane.