At a glance

- Increasing global battery demand is raising the need for a circular battery value chain

- EV battery retirements alone could surpass half a million vehicle batteries every year by 2030

- The battery materials recycling market is expected to reach US$64 billion by 2032

Batteries are hidden all around us in plain sight. Since the 1800s, an array of different kinds of batteries has transformed the world by offering portable power. Their vast range of applications includes everything from household electronic devices and smartphones to vehicles and even life-saving medical instruments.

But batteries pile up if they are not recycled – consider that in the United States alone, people buy billions of batteries every year. And with global demand for batteries only increasing, there is a growing need for the battery value chain to become circular – allowing more batteries to be reused and recycled. This is important for a number of reasons, not only because used batteries pose fire and contamination hazards, but also due to environmental and supply considerations given the scarcity of critical minerals.

In our latest edition of “Getting to know,” let’s explore this important issue further!

Advancing the circular battery value chain

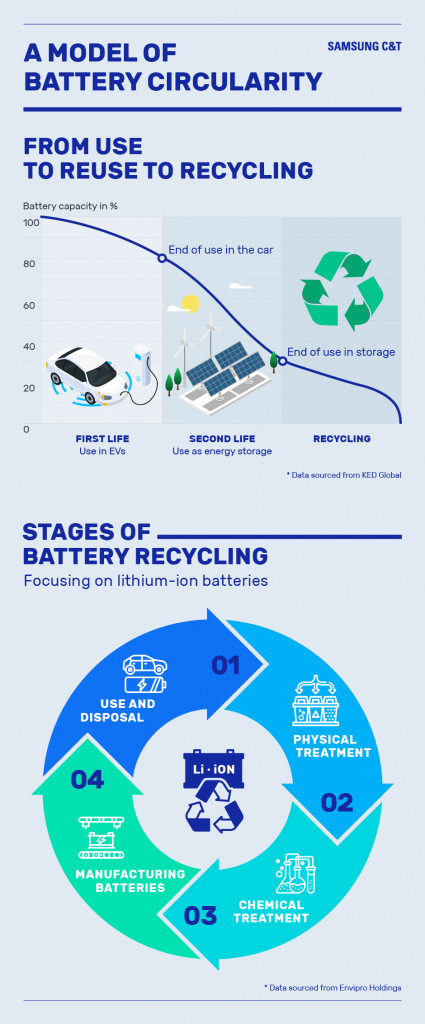

Rather than ending up in landfills, batteries can go through various stages before they are ultimately recycled, completing a circular value chain.

A good example of this chain begins with electric vehicle (EV) batteries. Consider that EV battery retirements alone could surpass half a million vehicle batteries every year by 2030 – and that each EV battery weighs around 454 kg on average! After several years of use in an EV, batteries may no longer be optimal for this purpose – but will still typically have around 80 percent of their original capacity. Instead of being discarded, used EV batteries can begin a second life in another application such as energy storage. After this stage, they may be ready to be recycled, which involves physical and chemical treatment, manufacturing, and starting over with new batteries.

The materials that add value to battery recycling

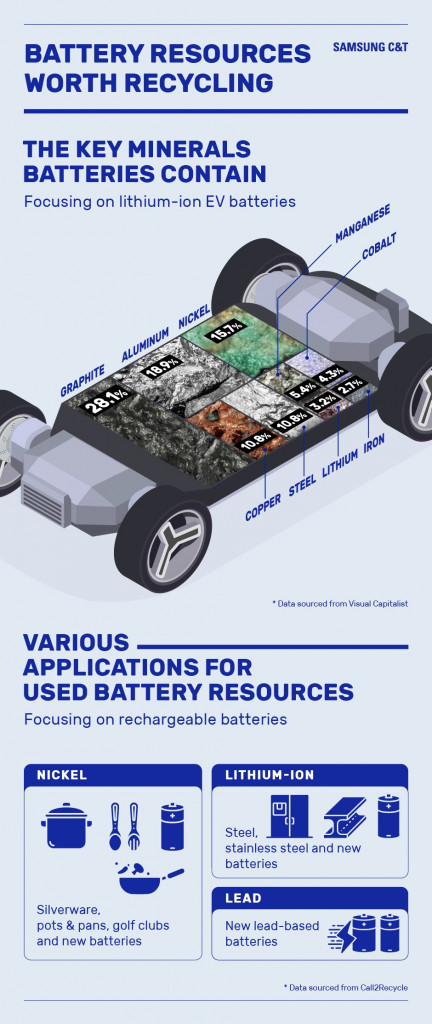

One of the main reasons that EV battery recycling attracts so much attention these days is that they rely on scarce critical minerals such as lithium, nickel, and cobalt in addition to metals like copper, steel, and aluminum. Compared with many of the smaller batteries we use on a daily basis, EV batteries boast a large size and high performance, offering stakeholders a more abundant supply of those minerals when they are extracted from retired batteries. Recycling EV batteries also relieves pressure on having to mine for new sources.

Yet, materials sourced from recycling batteries can find their way into a number of other applications. For instance, steel and stainless steel can be produced from used lithium-ion batteries, while pots, pans, and even golf clubs can be made out of used nickel batteries.

Battery recycling’s market outlook

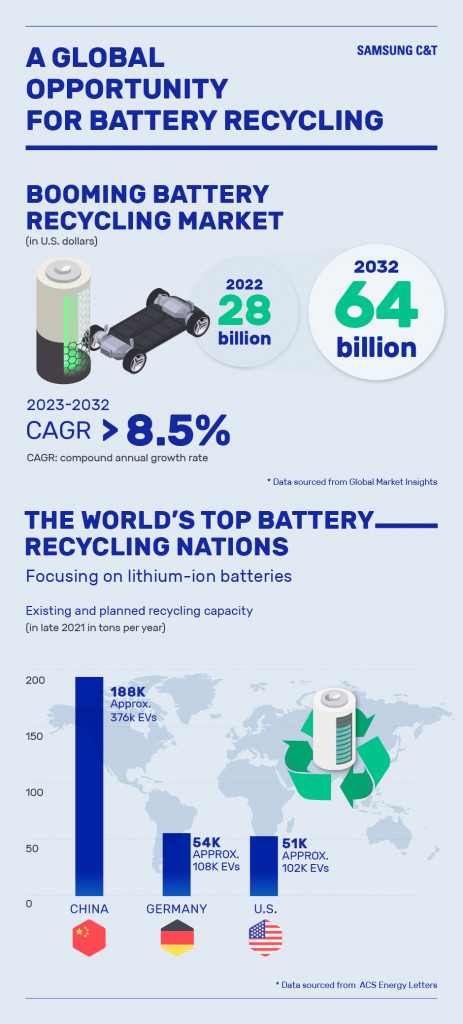

There are significant opportunities for companies and stakeholders participating in the battery recycling chain. They are being further boosted by eco-friendly government policies seeking to ensure that global resources aren’t wasted.

China has leapt ahead when it comes to its expanding battery recycling capacity, but the United States and Europe are also following suit – and the significant potential of the battery materials recycling market is underscored by the forecast that it will reach US$64 billion by 2032, up from US$28 billion in 2022.

Where does Samsung C&T come in?

As we have seen, it is not only essential from an environmental perspective but also potentially lucrative to become involved in and help build the battery recycling value chain. Under idealized conditions, recycled battery materials could supply 60% of cobalt, 53% of lithium, and 53% of nickel globally by 2040.

Samsung C&T Trading & Investment Group is already participating in the recycling value chain of core renewable battery materials such as nickel and cobalt and continues to strengthen its eco-friendly business portfolio by seeking new opportunities through partnerships with competent overseas companies. With more people, companies, and governments joining in, it won’t be long before battery recycling is a full-fledged example of a circular economy.