Quantum leaps in digital technology is revolutionizing the construction industry. Automation and sophisticated analytical tools are not only helping companies resolve long-standing challenges but are also transforming building methodologies in projects of all scales. With the gradual adoption of processes such as prefabrication and smart robotics, the World Economic Forum estimates that full-digitization of the construction industry could generate 12%-20% in annual cost savings.

One of the fields which is reaping the benefits of the Fourth Industrial Revolution is power plant construction. As a global leader in constructing power plants, Samsung C&T is taking an active role in advancing the technological front of the field. From training to project management, and even maintenance, smart technology has much to offer.

Virtual Learning

Construction costs usually decrease as technologies mature and experience is gained over time. But in the field of nuclear power plant construction, a recent analysis found that such projects are becoming more complex over time with the costs rising rather than falling. The result is that there are more delays in nuclear power plant construction – close to 20% of the rising costs since 2010 can be attributed this factor alone.

Detailed training is the best form of preparation. Augmented Reality (AR) and Virtual Reality (VR) technology offers junior nuclear engineers unmatched level of accuracy in their training program. GE, for example, employed VR to teach young engineers how to maintain turbines in nuclear power plants that were installed decades ago. By recreating scenarios as close to reality as possible, AR and VR helps engineers gain valuable experience without any risks.

Starting in September, Samsung C&T’s Plant Engineering team will use VR to train engineers before they enter the field. Designed to mimic real-life nuclear plants, the VR system features a guided tour and offers junior engineers opportunities to explore the machineries in a controlled environment. By allowing trainees understand how nuclear plants operate both on a micro and macro scale, the program helps reduce potentially costly errors when they enter the field.

Precise Planning

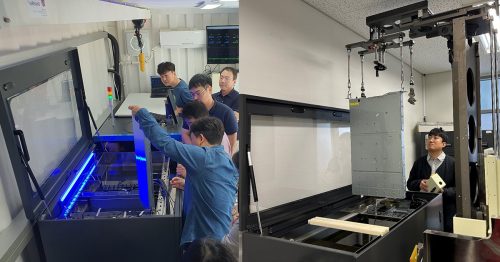

Part of the challenge in power plant construction is installing complex machineries. Assembling the network of tight-knit components requires precise spatial planning and measurement. The arrival of laser scanning technology has allowed engineers to visualize and measure spaces with unmatched level of accuracy.

With the help of experts from the Equipment Group, Samsung C&T’s Plant Engineering Team developed a laser scanning system to expedite the design process. Utilizing the latest laser scanning technology, the system creates a precise 3D rendering of power plant components. By superimposing the renderings on 3D models of the plant, engineers can identify potential problems early on. The new system has already been tested at several sites in Bangladesh and Morocco, generating positive results.

Precise Engineering

For decades, power plant engineers relied heavily on 2D blueprints while working on site, even though many would prefer to work with 3D models as they are more accurate. However, without a computer that is both powerful and portable, flat renderings remained a staple on construction sites – until now.

The computing power of the latest mobile devices makes it possible for engineers to view 3D models wherever they go. Recognizing the benefits of portable 3D blueprints, Samsung C&T’s Plant Engineering Team developed the Mobile Review app to provide quick access to detailed drawings via mobile tablets. The app is currently being used at a project in Algeria. The app helps engineers identify problems in advance and enhances communication between different teams on site.

Streamlined Management

Not so long ago, Artificial Intelligence (AI) only existed in the realms of science fiction. But recent advances in the field of AI has turned fiction into reality.

The emergence of AI holds vast potential to simplify the construction process of power plants. AI systems could help engineers identify the most efficient construction process. Equipped with sensors and GPS, autonomous construction machineries and vehicles can potentially improve safety at construction sites. With greater automation and precision embedded in the construction process, AI could greatly enhance the efficiency of power plant construction.

Smart Maintenance

The benefits offered by digital and smart technology extend beyond the construction phase, as the latest technological innovations can facilitate the maintenance of power plants.

Drones, for example, help engineers access remote parts of the facility for inspection. They can offer an alternative view of the components to identify a wide-range of problems, including cracks, leakages and missing parts. Meanwhile, building information modelling centralizes various types of information about the building for effective management. Some power plants have also integrated wireless field sensors to monitor components, allowing engineers to repair equipment before they fail.