The world of work keeps changing. As workers these days in countries like Korea are more interested in a better work-life balance and in focusing on more interesting and meaningful work, the number of working hours is being reduced or capped. At the same time, technological developments have led to the rise of robotic process automation (RPA).

Global research and advisory firm Gartner defines RPA as a productivity tool that allows a user to configure one or more scripts, which some vendors refer to as “bots,” to activate specific keystrokes in an automated fashion. The result is that the bots can be used to mimic or emulate selected tasks, or transaction steps, within an overall business or IT process. Whereas in times past it was mainly factory work that could be automated through machines, now office jobs are open to that revolutionary change through RPA, making the work more efficient and allowing workers to focus on more meaningful tasks.

How does Robotic Process Automation work?

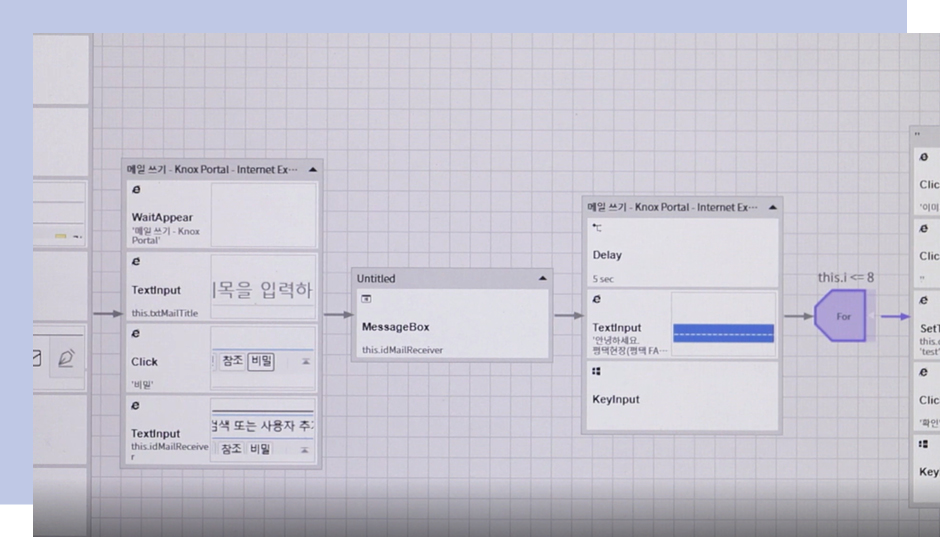

How can RPA replace a human in carrying out computer-based tasks? Workers write a workflow scenario document that a specialist RPA developer uses together with interviews, computer logs and actual video recordings of what appears on computer screens to write automation codes. Some RPA Solution developer companies are also testing ways to automatically log and analyze steps taken by workers to then suggest new areas where automation can be introduced.

Of course, not all tasks are suitable for process automation. In general, they must involve standardized procedures and they must be repetitive tasks that do not require human decision-making. Another optional feature is that tasks in which data is transferred between internal and external systems are ideal for automation. The advantage is that not only is work made more efficient, but also human error due to incorrect copying of data can be avoided.

Who’s using RPA now?

According to a report prepared by Fortune Business Insights, “The global robotic process automation (RPA) market size was USD1.39 billion in 2018 and is projected to reach USD6.81 billion by 2026.” Here are some examples of areas in which RPAs are already used. Korea’s four leading commercial banks ― Shinhan, KB Kookmin, KEB Hana and Woori ― adopted RPAs in 2016 to raise productivity. NongHyup Bank already has 120 RPAs carrying out 39 tasks. U.S. retail chain giant Walmart aims to install robots in its stores by the summer of 2020 that will trundle through the shelves of its outlets to check stock levels and price data. This case actually involves physical robots moving about, not just automated scripts. Korean home-grown RPA firm Edentns was selected by the Guam Power Authority to automate some of its tasks after out-competing a globally renowned rival in a performance test.

RPA adoption in the construction industry

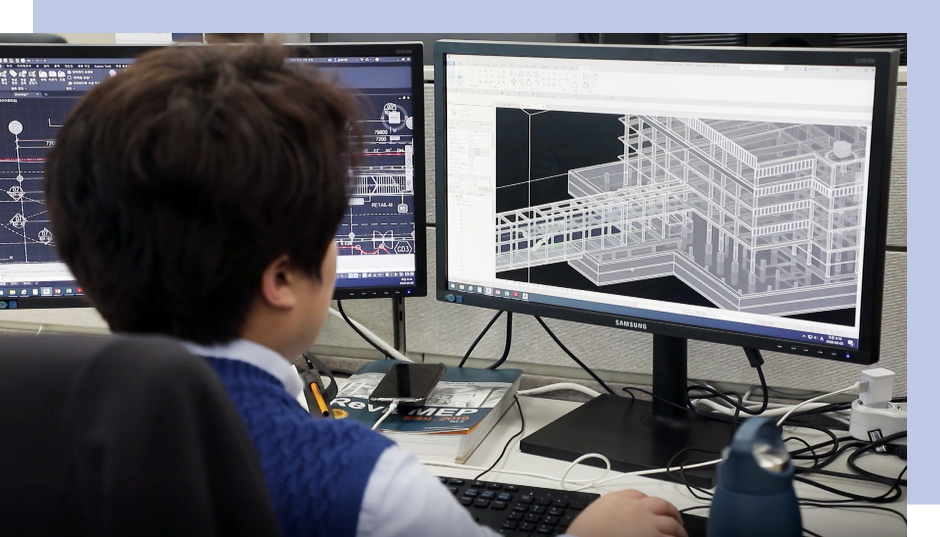

Samsung C&T’s Engineering and Construction Group is beginning to implement RPA at construction sites, including at its Pyeongtaek P2 semiconductor and memory chip manufacturing plant site. Six tasks have already been automated and this number is expected to grow to 12 in the first half of this year.

Kim Hyo-hwan from the Smart Construction Group who is in charge of RPA adoption and development at Samsung C&T’s Engineering and Construction Group explained that the “digital transformation” of the construction industry is slower than other industries, so there are lots of difficulties in implementing RPA. Nevertheless, said Kim, “Tasks that are indeed suitable for automation – often tasks that involve simple repetitive clicking – will quickly switch over, and technology in the area of computer recognition and judgment is developing rapidly too, so we expect to see some big advances in the near future.”

RPA adoption in the construction industry

Kim Rak-young, who is manager of the Pyeongtaek FAB 2 Line at Samsung C&T’s Engineering and Construction Group, said that the people working alongside RPA systems are working together with developers to prevent errors and improve the processes. “When errors do happen, it’s mostly due to inputting errors by humans,” he said. When asked what the workers could now do thanks to time saved, Kim said, “By handing over the doubled-up tasks of document review and inputting, we’re now able to focus instead on examining construction blueprints or specifications, or checking materials and equipment. That has increased our capacity.”

The world of work keeps changing

On both the company side and the worker side, we see every day that the world of work keeps changing. Companies want more efficient processes and workers want more meaningful and interesting jobs. In Samsung C&T, the Engineering & Construction Group is opening a smart work environment using RPA and the Trading & Investment Group is also creating a more efficient work environment by adopting RPA to share market conditions and issue transaction specifications.

Through the adoption of RPA, many boring repetitive tasks will soon be done by computer scripts, leaving humans to work on what they were trained to do. Samsung C&T’s Engineering & Construction Group and Trading & Investment Group hope to be at the forefront of showing how robotic process automation can change things for the better in the work environment, so that engineers can work on creative solutions to problems, not waste their days clicking mouse buttons.