Now is the time to construct buildings by printing! One of the most exciting new technological developments of the last two decades has been the invention and commercialization of 3D printing. Once the stuff of science fiction, it is now very real, and is being used in fields as diverse as biotechnology and manufacturing, and we are even starting to see it used in hospitals to make prosthetics or to create cell moldings during surgery. The construction industry is not about to be left behind by this innovation.

Architectural 3D printing technology has been around a since the early 2000s and its usage is growing. Let’s learn more about what 3D printing is, how it is impacting the construction industry, and what efforts Samsung C&T is making to develop this technology.

3D printing technology and construction

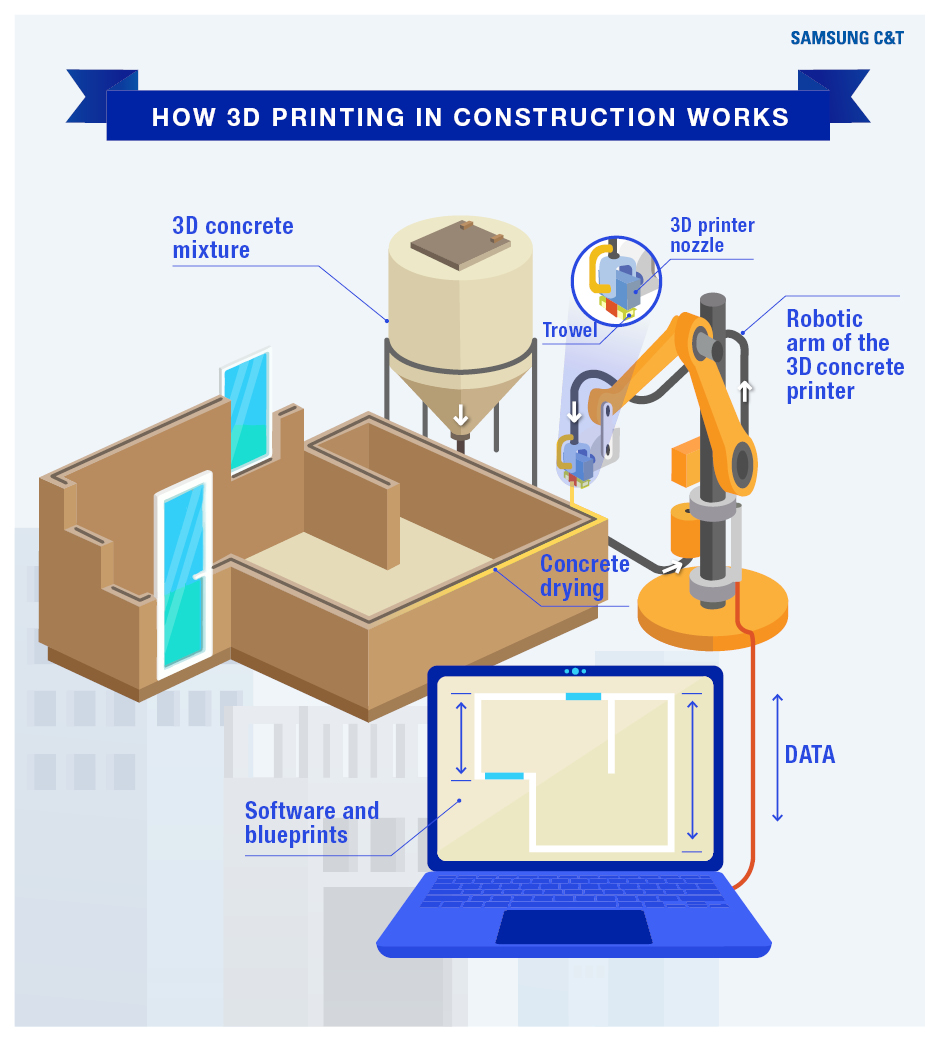

The principle of 3D printing is easy to understand. Also called additive printing or manufacturing, it involves depositing layer upon layer of material using a printer head that basically resembles the one seen inside an ink jet printer. The material to be deposited can vary from concrete to metal, polymer, and resin, and it fuses or binds with the previously deposited layers. Key to this process is that the material is not deposited haphazardly, but follows a 3D model that has been created on computer using CAD software.

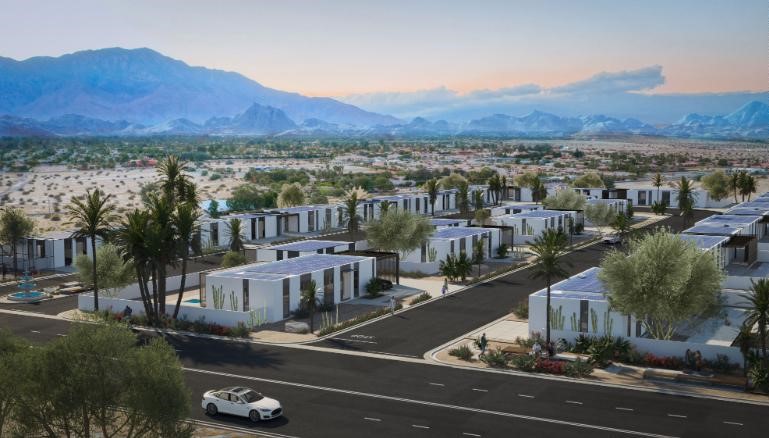

In its early days, 3D printing used in construction was able to create 3D models such as landscaping bricks or ornaments, prototypes, and small non-structural building parts. But further development of the technology means that it is now able to be used to create entire buildings.

There are several advantages to using 3D printing technology. Firstly, it reduces the overall construction period. Next, there is a reduction in safety accidents through reduction of manpower input. Thirdly, costs can be reduced.

Eco-friendly construction due to less construction waste is another benefit. In fact, a recent study found that depending on the type of cement used, a 3D printed building can show significant savings in both construction waste and energy use throughout the building’s life cycle. Moreover, it can reduce carbon dioxide emissions immensely.

With all these advantages, 3D printing construction technology is also useful for quickly preparing residential facilities in disaster areas, places with high numbers of displaced people, and conflict zones.

The prospects for 3D printing construction

A recent market survey found that the size of the global 3D printing construction market was 1.4 billion USD in 2021, and is expected to grow sharply to 750.8 billion USD by 2031, eight years from now.

If research into architectural mechanics, 3D printing technology, and artificial intelligence control technology continue apace, it will be possible in the near future to design a simple house directly with a smartphone app and build it with a 3D printer.

Barriers to the uptake of 3D printing technology in construction include the high initial investment cost, that fact that it is not yet possible to build a fully completed house with only a 3D printer, and the lack of certifications, safety standards, and regulations in most countries for buildings made by 3D printing.

Despite the high – and steadily growing – interest in the construction sector, as well as the work by several research and development (R&D) organizations and manufacturers of 3D printers, the market for related tech is still relatively undeveloped. This means that the field is still a so-called “blue ocean,” and opportunities abound.

If expectations that the technology will continue to advance are fulfilled, it has been predicted that 3D printing construction will play a decisive role in the development of space. In October 2020, NASA announced that it has started research building habitats on the moon and Mars in partnership with a 3D printing company.

Samsung C&T jumps into this blue ocean

Samsung C&T Construction Division is applying 3D printing technology to construction sites, such as creating faux landscape walls through 3D printing technology at the housing redevelopment site in Yongdu District 6, which is currently under construction.

In addition, in April this year, Samsung C&T Engineering & Construction Group signed a business agreement to jointly develop technology for a robotic arm-based 3D printer and to use it to build non-load-bearing walls.

This R&D plan is to develop core technologies for the future smart construction industry, with the goal of solving problems such as safety issues and securing labor at construction sites, reducing costs, improving productivity, realizing ESG management targets, and constructing non-load-bearing walls.

Through this agreement, Samsung C&T will continue to innovate and progress 3D printer equipment technology, construction technology, and materials technology. In addition, Samsung C&T plans to use the technological outcomes not only in the existing 3D architecture and landscaping fields, but also in various civil engineering fields, and gradually expand the distribution and application of 3D printers for construction.

Samsung C&T E&C Group aims to create an ecosystem that can utilize 3D printing throughout construction and preemptively secure source technologies to enhance technological competitiveness and reduce safety and quality risks.

The field of 3D printing construction is still nascent, but considering the interest and technological growth so far, the future changes in constructing buildings with printers are highly anticipated.