Otelinox is the focus of this latest installment of our Office Spotlight series, which aims to highlight the efforts of Samsung C&T Trading & Investment Group’s dozens of offices worldwide.

Around 80 kilometers northwest of the Romanian capital Bucharest, we find Otelinox stainless steel precision mill in the picturesque surroundings of Targoviste – for a quick Romanian language lesson, otel means “iron” while inox translates into “stainless.”

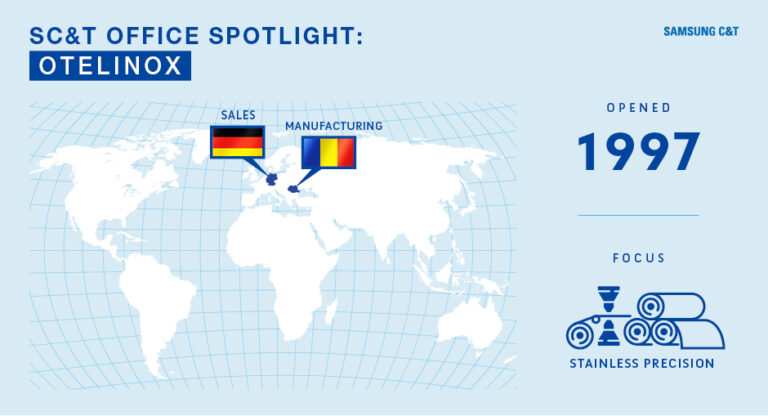

Otelinox is the producer of cold rolled stainless steel wide coils and strips in Eastern Europe. With a production capacity of around 66,000 MT/year, Otelinox exports its products within Europe, as well as to Asia, North America, and beyond, supplying various industries from the automotive sector to construction. Its sales team is based close to Frankfurt, Germany.

First commissioned in 1974 as a state-run entity, Samsung C&T has been in charge of Otelinox since 1997. We covered Otelinox’s background in more detail here, but in brief, Otelinox has moved away from its former low-profit bar business and shifted its focus towards precision stainless steel since coming under Samsung C&T’s ownership.

In this article, we aim to better grasp Otelinox’s efforts by finding out more about stainless steel.

How stainless steel shines in our daily lives

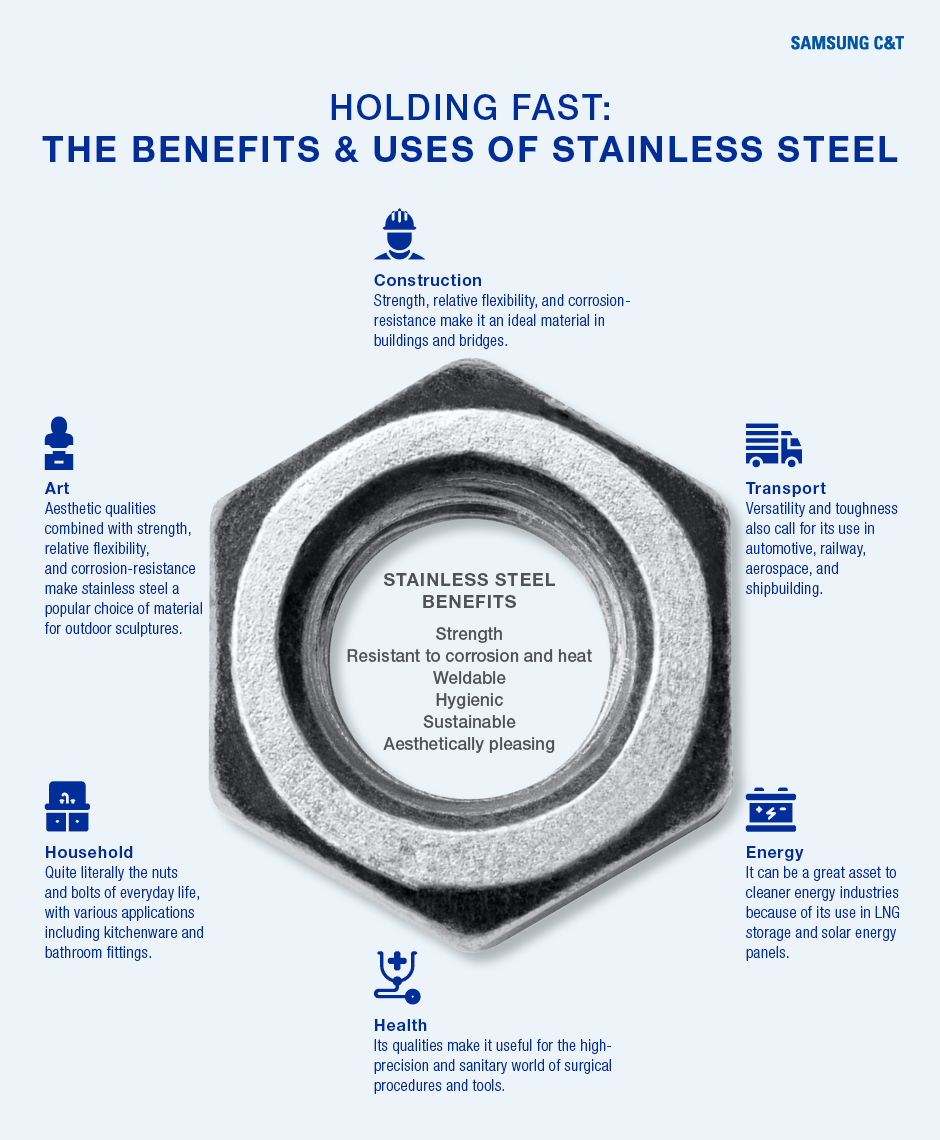

Stainless steel may be defined as “a form of steel containing chromium, resistant to tarnishing and rust.” Various innovators started to recognize the corrosion resistance of iron-chromium alloys throughout the 1800s, and by the time stainless steel was invented in the early 20th century, it had become clear that this new material would have an impact on a wide range of applications – from ships and bridges to gun barrels and cutlery.

There are in fact more than 100 grades of stainless steel, with different quantities of alloys combined for different purposes. The most common type, 304 grade, is used for various household and industrial applications and contains around 18 percent chromium and 8 percent nickel.

Generally, cutlery and kitchenware are well-known applications for stainless steel, along with power generation, food production, medical implants, automobiles, and other industrial uses.

A clean and eco-friendly commodity

The environmental benefits of stainless steel also reach far and wide. Consider those long-lasting stainless steel products many of us use in our homes. They can be reused over and over again thanks to the material’s durability.

Stainless steel is also praised as an alternative to single-use plastics, even for things like straws. In addition to being reusable, this material is also easily recycled, and it is estimated that about 80 percent of stainless steels are recycled at the end of their life, according to the International Stainless Steel Forum.

Stainless steel versus aluminum

While there are many types of stainless steel, a general comparison may be made with aluminum. Both materials have extensive applications, many of which overlap – as household consumers will be aware when buying kitchenware and cooking equipment.

However, there are key differences between them, which offers one an advantage over the other depending on what they are being used for. For example, stainless steel is less reactive with foods, while aluminum can affect the color and flavor of what we eat. Another benefit of stainless steel over aluminum is its strength, although it is around three times heavier than aluminum. Stainless steel is also more corrosion-resistant as it contains chromium and is non-porous, whereas aluminum’s surface turns white when oxidized and is prone to pitting.

On the other hand, aluminum is not only cheaper but has better thermal and electrical conductivity, which is why it is used for products like car radiators, air conditioning units, and high-voltage overhead power lines. Finally, although aluminum is softer and more malleable, stainless steel is easier to weld.

As we have seen, stainless steel is vital to a variety of industries, but it is not a straightforward material. It comes in numerous grades to suit a range of purposes, including those of Otelinox’s target industries for its cold rolled stainless steel wide coils and strips. And just as the world is continuously demanding stainless steel, Otelinox is always aiming to do better.

“Our staff are educated in the spirit of continuous improvement, development, and innovation,” says Principal Professional KyungGuen Choi. “After all, the arrogance of success is to think that what you did yesterday will be sufficient for tomorrow. We will keep striving to expand and improve, as Otelinox aims to realize its vision to be a world leader in stainless steel high precision products.”