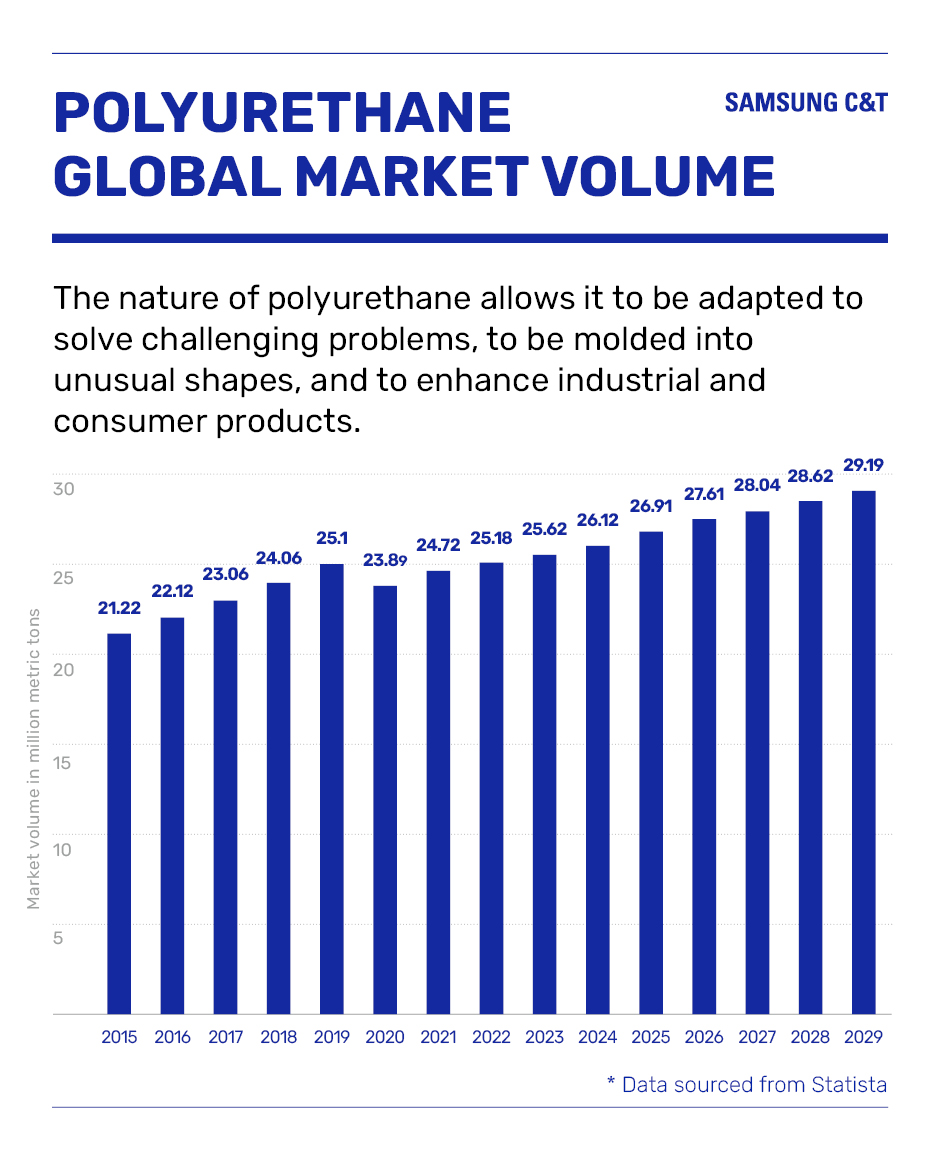

The global polyurethane market was recently described as a USD 100 billion opportunity, driven by demand for various applications, including furniture and building insulation.

Moreover, this material itself is continuing to evolve. For instance, there are ongoing exciting developments with the creation of biodegradable polyurethane. But what is polyurethane and what distinguishes it from other plastics?

Hidden in plain sight

First invented by German industrial chemist Otto Bayer in the 1930s, there are actually different kinds of polyurethane. And while it might appear to be just another type of plastic, it is distinguished by a reaction involving particular combinations of compounds. Note that although the terms polyurethane and urethane are often used interchangeably, they are actually different – with polyurethane being made of multiple urethane units.

During the process to manufacture polyurethane, different steps will produce different results depending on the desired application. For instance, when carbon dioxide is used as a blowing agent, you get a soft foam material ideal for a sofa or mattress. On the other hand, a gas like pentane can be trapped in polyurethane to create a rigid foam that might be used for insulation. And it can be harder still, being used for products like rollerblade wheels.

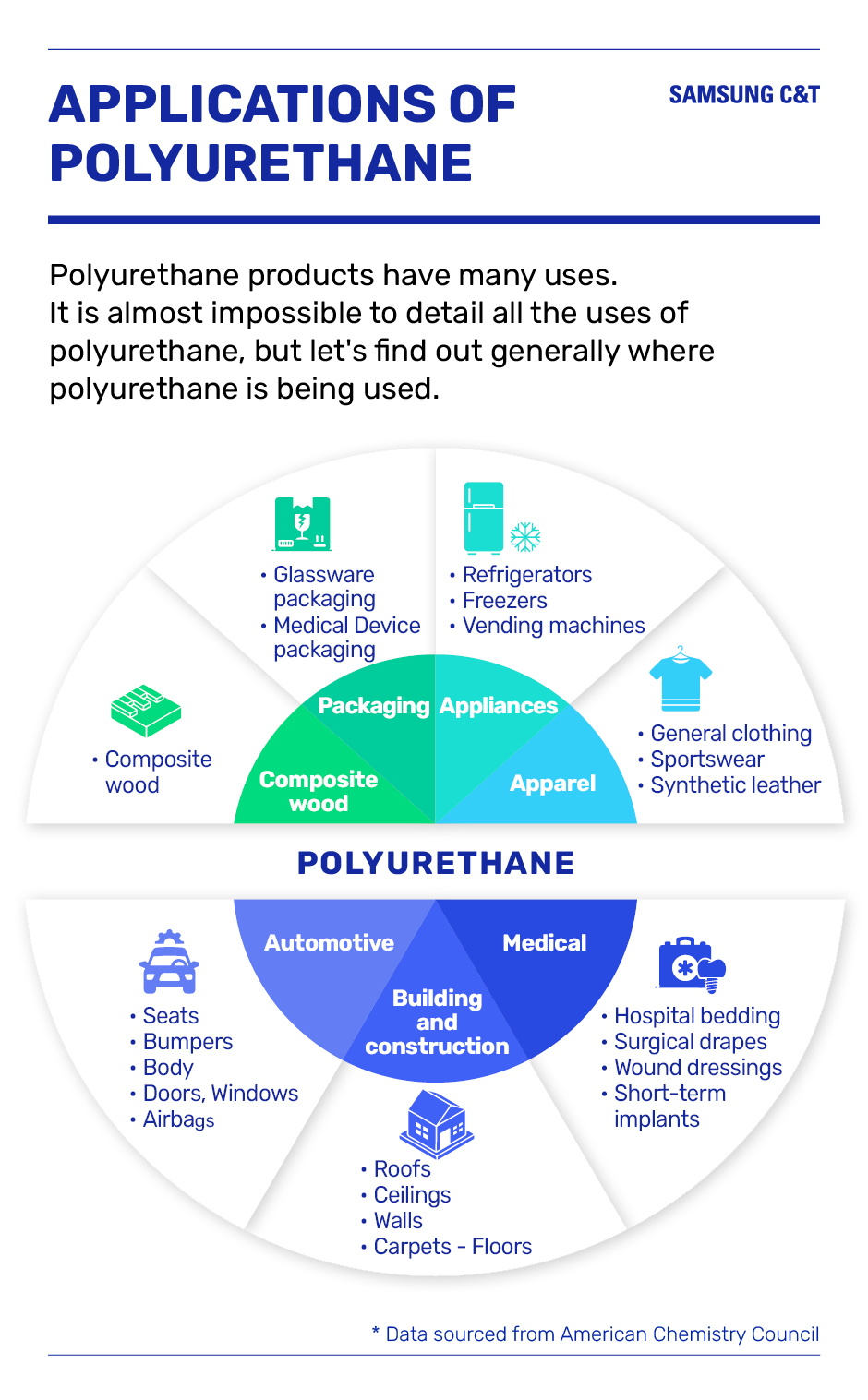

Soon after its invention, polyurethane was used as a rubber replacement during World War II. During the decades since, it has found a wide variety of applications. In fact, most of us encounter polyurethane on a daily basis, hidden in plain sight.

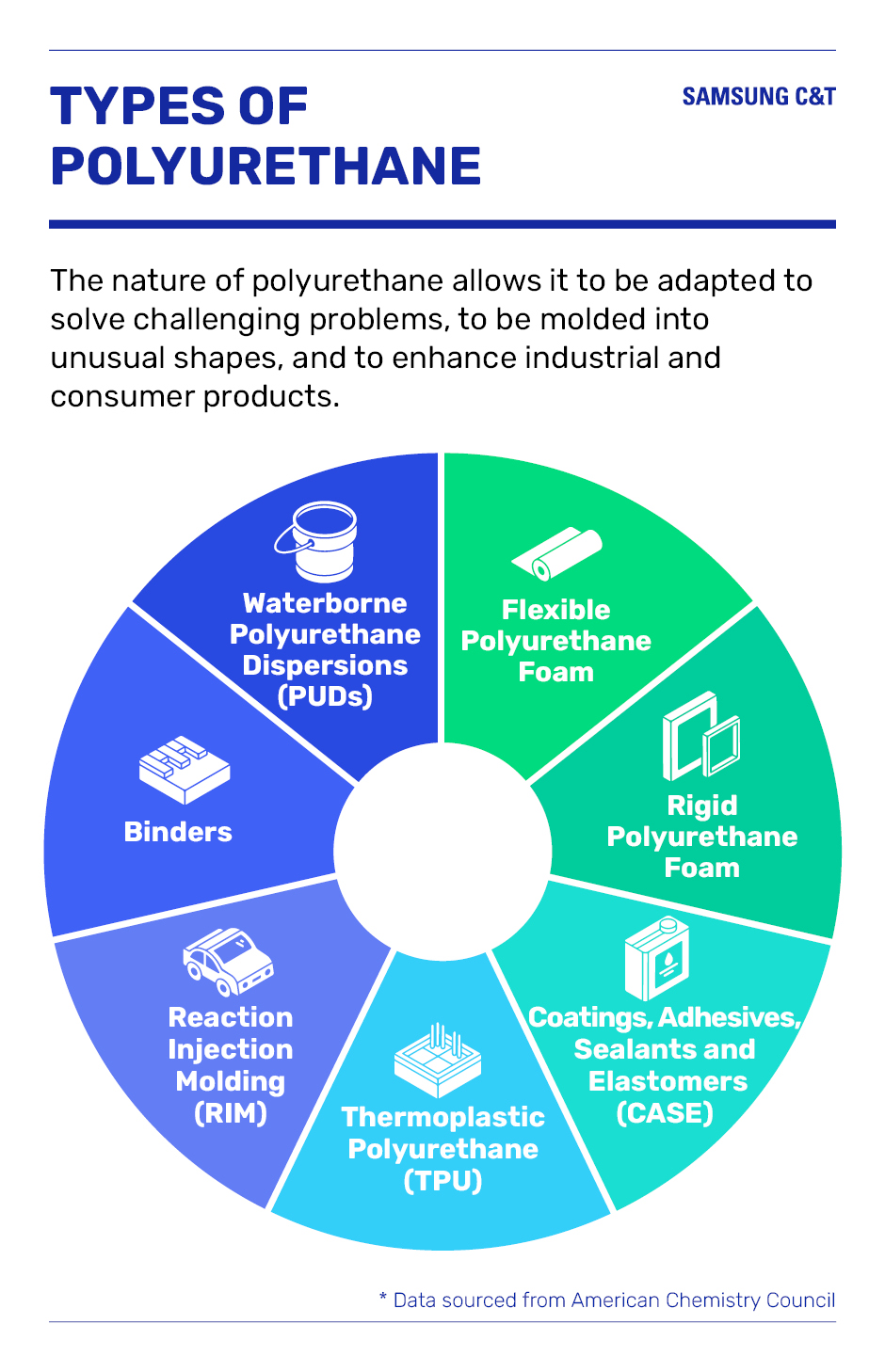

Many kinds, many uses

The two main kinds of polyurethane foam are flexible and rigid. Flexible polyurethane foam is usually used for the padding comfort enjoyed in furniture and in vehicles, while rigid polyurethane foam is generally applied to energy-efficient insulation.

Beyond foam, thermoplastic polyurethane is highly elastic and flexible while being resistant to wear and tear, making it ideal for construction applications and footwear. Reaction injection molding is another kind of polyurethane that is particularly resistant to heat. And we also find polyurethane coatings, adhesives, sealants, and elastomers, which support the durability and performance of a range of products.

Versatile advantages of polyurethane

The various types of polyurethane, as well as their many applications, are made possible because this is such a versatile family of polymers. The kind of polyurethane you get greatly depends on the structure of the polymer backbone.

Broadly speaking, polyurethane is prized for some key advantages. It can be both extremely tough and very flexible; be load-bearing and light; be soft enough to use as memory foam and firm enough to insulate a home; and be resistant to high impacts, heat, radiation, and oil.

While there are concerns about the widespread use of plastics around the world, there is hope in the development of more sustainable solutions. For example, much investment has gone into chemical recycling technologies that allow more efficient polyurethane degradation, reducing the time, cost, and energy required. Moreover, research has shown how polyurethane foam samples taken from a shoe could start to degrade in just four weeks when exposed to various marine organisms in ocean water.

As a result of polyurethane’s benefits and long list of applications, we find the significant market opportunity we referred to earlier.

Where does Samsung C&T fit in?

Amid high global demand, Samsung C&T Trading & Investment Group is also participating in trading of polyurethane raw materials. Samsung C&T traders sell Asian propylene oxide, polyol, methylene diphenyl diisocyanate (MDI), and toluene diisocyanate (TDI) to many different buyers around the world, including China, the Middle East, West Africa, and Latin America.

In addition to trading, Samsung C&T invested in a polyol manufacturing plant in Nanjing, China in partnership with a Korean polyol manufacturer in 2006, and has been successfully managing domestic sales of polyol in China for more than 15 years – establishing concrete milestones, especially in the automotive seating industry.

As the market for polyurethane grows, and with the development of more diverse recycling technologies and biodegradable polyurethane, Samsung C&T is keeping an eye on this promising area of business and shall keep seeking opportunities in the expanding polyurethane feedstock sector.