The Fourth Industrial Revolution, which is seeing the digital meet the physical in revolutionary new ways, has taken hold over so many aspects of our lives. Accordingly, a wave of smart construction powered by IoT, AI and other such technologies is blowing through the construction industry, and the Samsung C&T Engineering & Construction Group is at the forefront of incorporating it into best practices.

Due to the nature of the work undertaken, the construction industry is responsible for 20-30% of all serious occupational injuries. The US Bureau of Labor Statistics, in its yearly reports, consistently lists construction in its top 10 of most dangerous jobs.

But Samsung E&C is committed to safeguarding its processes. Hence, E&C’s very own specialist task force dedicated to bringing construction into the new age has developed its Smart Equipment Management System for Safety (SEMSS) – the very latest in site safety frameworks. SEMSS has already obtained KC certification and is in the process of obtaining CE certification, so that this intelligent equipment supervision tool can become a mainframe of E&C sites both in Korea and overseas.

The Next Step in Safety

One non-functioning piece of equipment on a construction site can determine the productivity of an entire project. The scale and complexity of construction projects nowadays is constantly growing, and with this, so does a site’s reliance on heavy equipment to undertake these ambitious projects.

Key to managing this equipment is communication between machine operators and managers, especially in preventing the use of uninspected equipment on-site. But as the scale of projects continues to grow, inefficiencies can emerge in manual equipment checking processes – which can quickly lead to arbitrary judgements made and insufficient inspections carried out on equipment.

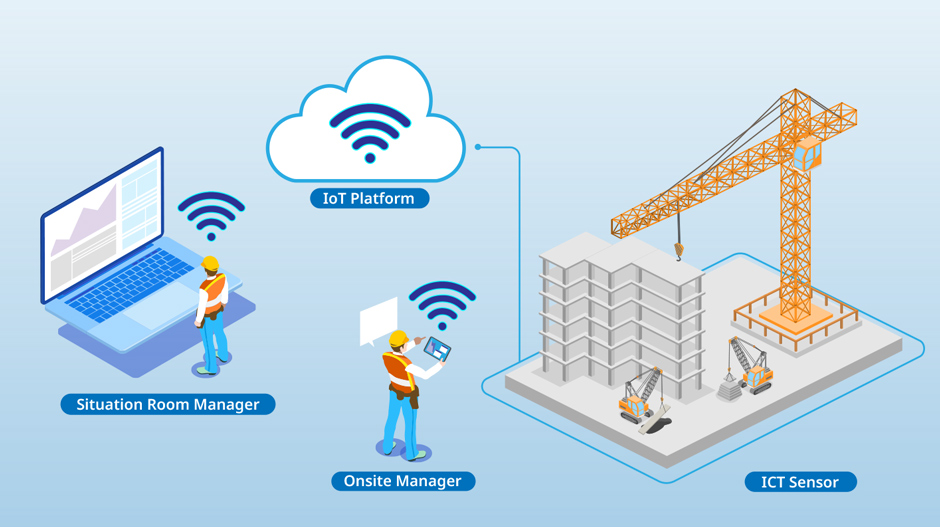

Acknowledging that inadequate inspection of large-scale machinery is a common factor in on-site accidents, Samsung C&T developed the automated IoT-based SEMSS to prevent such oversights. Its technology streamlines and ensures safety procedures across two key areas in the equipment management process – on-site monitoring and daily inspections.

SEMSS for Equipment Monitoring

Each piece of heavy equipment on a site has several indicators that display work data. After each usage, managers traditionally manually inspect the indicators to ensure machine health, a lengthy process that can cause inefficiencies – and on occasion, oversights – in a project’s process. Thanks to the intelligent reporting and cloud-based sharing of SEMSS’s IoT sensor network, managers can now receive this information straight to their smartphones as well as the main situation room of the site, allowing them to check and monitor equipment conditions anywhere and in real time.

SEMSS also goes one step further in safeguarding the construction site – the system can intelligently monitor any non-worker occurrences, such as strong winds or other unstable working conditions, and flag this to managers and those in the situation room. The resulting cross-check improves communication between operators, managers and their equipment, and helps the prevention of equipment-related accidents.

For heavy lifting equipment, the increased situational control and machine awareness offered by SEMSS is substantial. Previously, the capabilities of these vast machines could only be checked from inside the crane tower, but with the help of a specialized endoscope camera, SEMSS allows workers to monitor via smart device the lifting capabilities of multiple cranes and their working times simultaneously. An intelligent alarm system prevents any out-of-work usage as well as any over-capacity lifting attempts that previously could have resulted in serious mishaps.

SEMSS for Daily Inspections

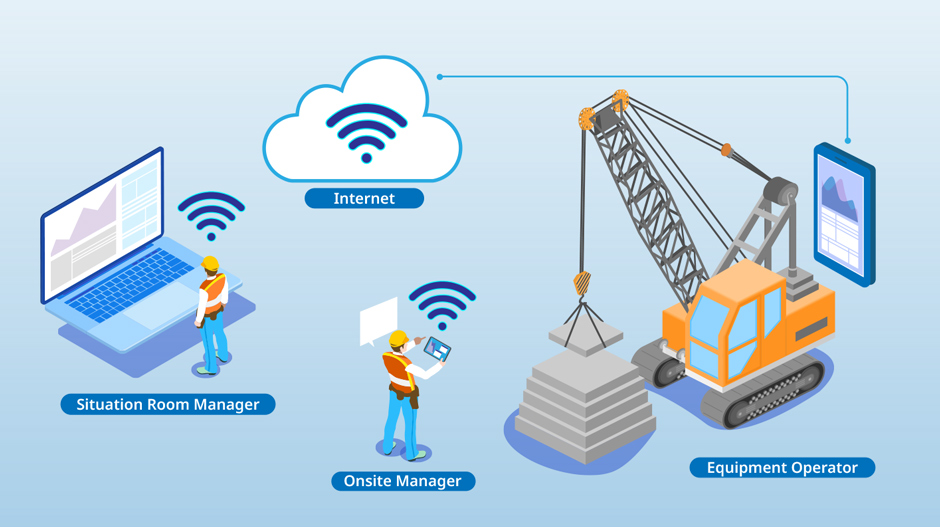

The daily inspection of machines on-site is one of the most important constants in keeping a project running smoothly and safely. Carried out by the machine operators but confirmed and approved by site managers, this process can be lengthy. Furthermore, the handwritten nature of these reports often leaves room for error, and the manual nature of the checks often leaves managers pressed for time. SEMSS streamlines this process – ensuring any inefficiencies are caught ahead of time.

With SEMSS, work operators use smartphones to take pictures of their equipment and type up their daily safety checklists and any notes; this is then sent directly to managers who can review and approve the inspections in real time. The use of technology eliminates any lag in the inspection process and cements the ‘monitor-before-work’ principle to all workers.

Most importantly, SEMSS technology locks down any equipment that hasn’t had its inspection approved in case of erroneous use and sends automatic reminders when equipment hasn’t yet been inspected to avoid a situation where hasty checks have to be done. Not only does SEMSS create better practices and safer equipment usage environments – the E&C Group aims to expand SEMSS to a wider range of its major equipment types by 2020 – but it also can improve the management efficiency of those who work with construction equipment.