With the rapid electrification of the world around us, we might overlook the way our portable and wireless devices get their power and how they are able to recharge.

From smaller gadgets like Bluetooth earbuds and smartphones to larger ones such as electric vehicles and satellites, many of the products and objects we rely on are rechargeable – if they weren’t, they’d essentially be useless.

With the development of lighter, smaller, and more efficient rechargeable batteries, our world has been transformed. So, what exactly are rechargeable batteries and why are trading companies paying attention to this subject?

A brief history of the rechargeable battery

The rechargeable battery produces electrical energy through chemical reactions and stores the electrical energy to charge the battery, thereby enabling the use of electrical energy semi-permanently. While the concept of a battery as a source of energy has been around for a long time, possibly even 2,000 years going back to the Parthian Empire, the first rechargeable battery was invented by French physicist Gaston Plante in 1859.

Using lead and acid, Plante created a technology that remains in use today, in regular car batteries, for instance – the kind used to start an engine, rather than power an electric vehicle. The main problem with the lead-acid battery is that the amount of electrical energy it can produce is low compared to its weight and volume.

The arrival of various kinds of nickel batteries from 1899 through the 20th century solved some of the lead-acid battery’s efficiency issues – but presented other problems, including efficiency and environmental issues.

The real breakthrough came in the early 1990s with the introduction of the lithium-ion battery, which has been a gamechanger in consumer electronics because it is energy dense and lightweight. Although it has the disadvantage of losing charge slowly when not being used, many modern electronic products use more sophisticated and efficient reusable lithium-ion batteries because of their high electrical energy production compared to low-cost nonrechargeable batteries.

The lithium-ion revolution

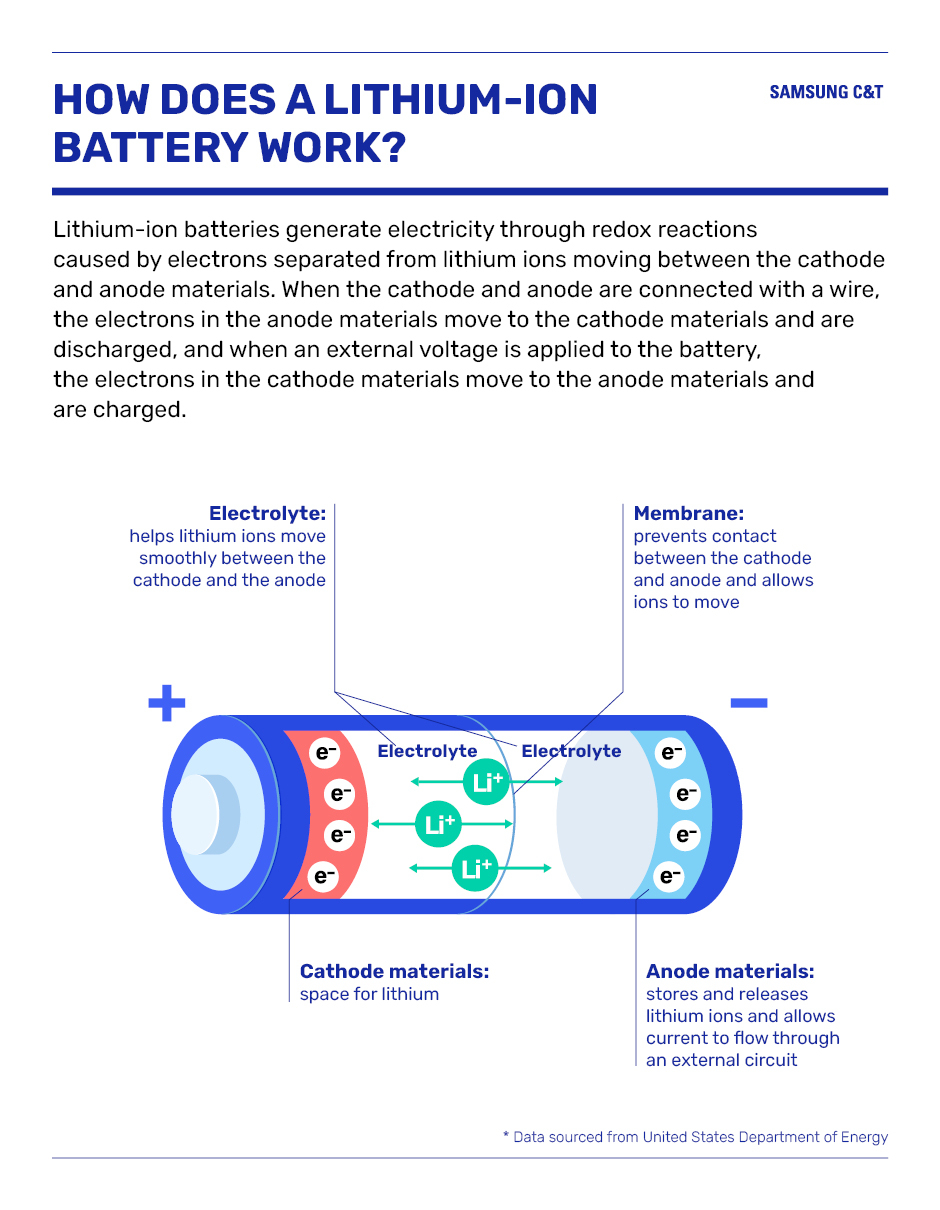

Let’s take a closer look at how lithium-ion batteries, which are a type of widely used secondary battery work to better understand this widely used technology.

Powering up the market

Already, smartphones and electric vehicles have created vast demand for lithium-ion batteries. But as AI and IoT technologies continue to expand, along with wearable electronic products, so too does demand for efficient rechargeable batteries. Other areas of rechargeable battery expansion include energy storage devices and smart grids.

Representative materials required for a rechargeable battery are lithium, nickel, and cobalt. In particular, lithium, a major material for rechargeable batteries, has been continuously increasing in production as demand for it increases, and global lithium production reached 100,000 tons last year. An electric vehicle lithium-ion battery pack that uses a rechargeable battery as an energy source requires 8 kg of lithium per unit and in the case of a smartphone battery would require about 2g of lithium for a 4,600mAh battery. Considering the global demand for electric vehicles and smartphones, it can be seen that the demand for raw materials according to the demand for secondary batteries is not small.

Therefore, it is not surprising that the rechargeable battery market has a bright outlook. In fact, the global lithium-ion battery market is expected to surpass US$182 billion by 2030, expanding at a CAGR of 18.1% from 2022 to 2030.

We should also note the need for flexible expectations for new types of rechargeable batteries, because new battery technologies are also emerging that will offer even greater efficiency – though the overall outlook for rechargeable batteries is very positive.

Where does Samsung C&T fit in?

As the market for rechargeable batteries grows in line with those expectations, there is an impact on various materials. This is why it is important for trading companies to work for a stable supply of metals such as nickel and cobalt. Samsung C&T T&I Group is trading in rechargeable battery raw materials such as cobalt and nickel, centered on the electric vehicle market, which is expected to grow in the future.

The Samsung C&T Trading Group is participating in a recycling business that collects eco-friendly battery metals such as nickel and cobalt from waste batteries and supplies them to cathode material manufacturers. In addition, the group is collaborating by investing in the construction and operation of a German rechargeable battery pretreatment plant, which is being promoted by a Korean recycling company.

In addition, Samsung C&T has signed a series of agreements with other companies ranging from clean hydrogen production to transportation and utilization in relation to the revitalization of the hydrogen economy, which has recently been attracting attention, and is striving to develop the hydrogen industry’s value chain.