According to one old saying, clothes make the man. If this principle can be extended to a building, then the exterior of a building “makes” the whole structure. When you think about the simplest kind of an enclosed building, there are four walls with a roof on top where the walls hold up the roof with the entire weight of the roof resting on the walls. In such a house, the walls must be made of strong, usually heavy materials in order to support the load. But in most modern buildings, especially skyscrapers, the weight of the upper floors and the roof are held up by an internal frame and not by the outer walls. This means that the outer walls can be made of much lighter materials like glass, aluminum, or even solar panels. These non-load-bearing walls are known as “curtain walls.”

Raising the curtain on modern building techniques

A curtain wall is defined as an external wall of a structure that doesn’t support the weight of that structure but merely serves to divide the inside of a building from the outside. As a rule of thumb, if you see a multi-story building with a lot of floor-to-ceiling glass windows in its facade, you are probably looking at a curtain wall (because glass is not usually strong enough to support the weight). The curtain walls are connected to the frame of the building by vertical elements called mullions. These mullions help to support the weight of the glass panels, aluminum siding, or whatever other materials comprise the curtain wall.

Although glass curtain walls were first employed in Great Britain in the mid-1800s, for instance on the Crystal Palace at the Great Exhibition in London in 1851, and in 2 buildings by architect Peter Ellis in Liverpool in the 1860s, they didn’t become common until the widespread rise of skyscrapers after World War II.

In general, there are two ways to attach a curtain wall to a new construction. There is the knock-down or knocked-down method, in which all the pieces necessary to make a curtain wall are brought to the construction site in kit form and are assembled and installed on-site. The other way is to assemble sections in a factory, transport them to the site and then raise them up as giant prefabricated pieces.

Why a curtain call?

There are four main advantages of using a curtain wall for the exterior of a high-rise building. First, curtain walls lighten the overall weight of a building. Because the outer walls no longer need to support the load of the upper floors, and merely divide the inside and outside of the building, they can be made of much lighter materials.

Second, both construction time and costs can be saved. In constructing a high-rise building, assembling the load-supporting framework takes a long time. Curtain wall panels can be prefabricated simultaneously so that they can be assembled as soon as the frame has been completed. Curtain wall materials are usually cheaper than heavier load-bearing materials and are also cheaper to transport.

Third, buildings with curtain walls can be structurally more resilient and high-performing than those with load-bearing exterior walls. This is because curtain walls are often better at absorbing and withstanding forces like wind sway and seismic tremors than heavier, more rigid walls. Depending on the materials and techniques used, curtain walls can also be better at blocking direct sunlight, controlling temperature, rainwater diversion, and external noise reduction.

Finally, there is the aesthetic advantage. A building finished with a glass or panel facade presents a sleeker, more modern and sophisticated appearance than a building with a bare concrete or brick exterior.

C&T: Curtains and towers

In the modern construction industry, Samsung C&T’s Engineering & Construction Group has worked on several prominent projects that feature curtain walls.

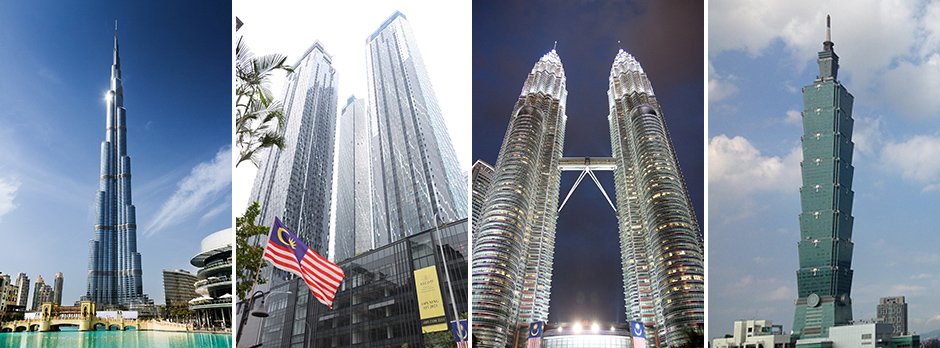

The exterior of the world’s tallest building, the 828-meter, 163-floor-tall Burj Khalifa in Dubai, consists of roughly 29,000 double-layered glass panels set in aluminum frames. The panels are coated with a special material that only lets in 20 percent of the light and 15 percent of the solar energy, and the whole facade is curved in such a way as to disperse sunlight.

The Star Residences in Kuala Lumpur also boast curtain walls. As the tallest residential towers in Malaysia, each of them is encased in opulent bluish-green glass decorated with diagonal white lines, and every exterior facing room features floor-to-ceiling windows. Also in Malaysia, Samsung C&T’s Engineering & Construction Group had previously used curtain walls on the Petronas Twin Towers, completed in the late 1990s as the world’s tallest buildings at the time and still titleholder of the tallest twin towers.

The next building to hold the title of tallest in the world, until it was surpassed by the Burj Khalifa, is the Taipei 101. Samsung C&T E&C worked on its construction, too. This 508-meter-tall tower features blue-green curtain walls made of glass and aluminum that keep out much of the sun’s heat and UV rays while also being able to withstand strong winds, seismic forces, and high impacts.

Thanks to their attractiveness in terms of aesthetics, construction time and cost, and high performance, curtain walls are unlikely to go out of fashion in the construction world any time soon. And Samsung C&T E&C is sure to be at the forefront of using this technique for many years to come.